Qingdao Decent Group proudly introduces its first generation of electric fusion furnace – a game-changing solution engineered specifically for modern fire assay laboratories requiring precision, safety, and unprecedented throughput. This industrial powerhouse represents a significant leap forward in fire assay technology, designed to meet and exceed the rigorous demands of professional testing environments.

The Unmatched Power of DECENT Industrial-Grade Fusion Solution

Fire assaying, the gold standard for precious metals analysis, remains the preferred process for many gold analysis laboratories. Fusion of sample and flux is a critical step in the fire assaying process, and a stable, high-performance sample fusion furnace directly impacts experimental results. That’s why Qingdao Decent Group developed this first generation of electric fusion furnace to deliver consistent, high-performance results that laboratories can trust day after day.

DECENT First Generation of Electric Fusion Furnace

Engineering Excellence in Every Component

Our first-generation electric fusion furnace is the result of our R&D team’s extensive market research, years of engineering experience, and extensive validation. Designed to accommodate 25 crucibles, it’s ideal for laboratories melting samples in batches. The furnace features a separate chamber design, which better protects the silicon-carbon heater and allows for easy replacement and maintenance. Compared to traditional chamber designs, it is more ergonomic for use and maintenance.

Our furnaces are compatible with a variety of crucible sizes to meet laboratories’ varying sample loading requirements. After field testing, our first-generation electric furnaces can reach temperatures up to 1200°C and offer precise temperature control.

Prioritizing Operator Safety

While the high temperatures generated during the melting process of fire assaying can completely melt even the most challenging samples, their effects can also pose significant safety risks to operators. Furthermore, hazardous chemical emissions generated during the melting process must be strictly controlled. That’s why our first generation of electric fusion furnace incorporates multiple safety features while emphasizing proper operator protection.

- Pneumatic lift door mechanism

- Leakage protection feature

- Automatic over-temperature alarm system

During the fire assay, all personnel must wear appropriate safety gear including:

- Certified safety goggles

- Aluminized heat-insulating protective clothing

- Aluminized protective gloves

These precautions are essential as fire assay procedures require trained assayers capable of performing these operations skillfully and safely. Our furnace design minimizes exposure risks while maintaining optimal workflow efficiency.

Seamless Integration with Your Existing Workflow

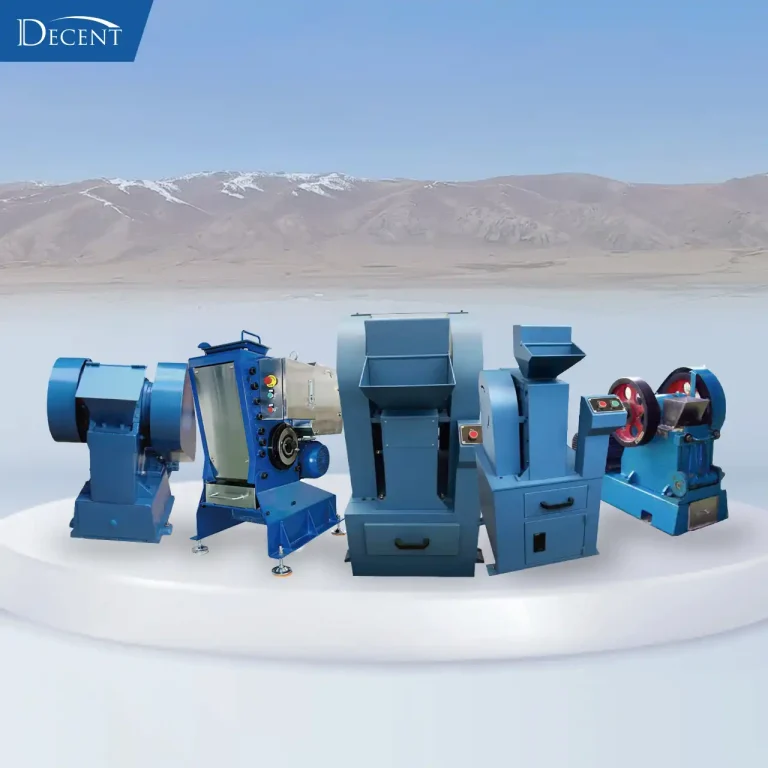

The true power of DECENT’s first generation of electric fusion furnace lies in its ability to integrate seamlessly with your laboratory’s existing equipment ecosystem. This furnace works perfectly with complementary DECENT Group products including:

- Manual and electric lofting forklifts for safe crucible handling

- Crucible mixers for consistent sample preparation

- Specialized crucible dumping systems

- Dedicated cooling carts

This integrated approach creates a comprehensive multi-sample loading and transfer system that transforms your fire assay workflow from a series of disconnected steps into a streamlined, efficient process. Laboratories implementing this complete system report up to 40% reduction in processing time compared to traditional methods.

Precision Engineering for Consistent Results

Unlike generic industrial furnaces, our first generation of electric fusion furnace is engineered specifically for fire assay applications. Our advanced temperature control system ensures uniform temperature within the furnace, which is crucial for achieving consistent sample melting results.

This consistent temperature profile eliminates variables that could affect analytical results, ultimately ensuring consistent analytical results.

Customization for Your Unique Requirements

DECENT first-generation electric melting furnace offers comprehensive customization options. Whether it’s a specific furnace size, a specific number of crucibles, or integration with existing systems, our team is dedicated to meeting your specific needs. This customization extends to all fire assay tools in our product line. From crucible designs to specialized handling equipment, DECENT creates solutions tailored to your specific workflow requirements and sample types.

Experience the DECENT Difference

When precision matters, when safety is non-negotiable, and when laboratory efficiency directly impacts your bottom line, the first generation of electric fusion furnace from Qingdao Decent Group delivers unmatched performance.

Learn more about our complete fire assay solutions.

Explore more information about fusion furnaces.