Speed-adjustable, precise and efficient Rotary Sample Divider

Projections indicate that by 2024 the global laboratory service market will reach a value of $17.7 billion (USD) up from $9.5 million in 2019. This massive growth is due to the increasing need for research activities across a number of industries.

Laboratory testing and analysis are something that requires a very high degree of accuracy at all stages. This is to ensure all processes and results are correct and precise.

Because of this, any equipment used must be high-quality and fit for purpose. Qingdao Decent Group has a high level of commitment to manufacturing and supplying the highest quality plant equipment available.

One such example is the rotary sample divider. For more information on what a rotary sample divider is and how it works, keep reading.

What Is a Rotary Sample Divider?

A rotary sample divider is a piece of plant processing equipment used to obtain representative samples from heterogeneous granular and powdered materials.

Heterogeneous materials are a mix of diverse or dissimilar ingredients. These ingredients can have sizes ranging from micrometers to millimeters, and the geometry of the particles can vary greatly.

How Do Rotary Sample Dividers Work?

The granular or powdered sample is injected into the sample divider. This is done in a free-falling manner. The speed must remain constant throughout the reduction process.

The feeder vibrates in a uniform manner. This ensures the sample is representative of the material as it is transported. It goes from the funnel mouth and through a stainless steel channel, which then deposits a number of separate samples.

These machines, and therefore the sample sizes obtained, vary in size for different purposes.

Various industries make use of samples gathered by rotary sample dividers, so samples must meet standard requirements. Because of this, these machines are carefully designed to be very precise and efficient.

The operator can control the adding speed and rotation speed, and these should be set depending on the material to give accurate results. A lower vibration amplitude gives a slow injection, while a high amplitude results in a faster injection.

Most rotary sample dividers will split the sample into an even number, commonly 6 or 8.

Applications of Rotary Sample Dividers

Rotary sample dividers are useful across a number of industries. Some of the more common are:

- Mining

- Pharmaceuticals

- Food (seasoning, cereals, etc.)

The most common, however, is laboratory use. Powders (especially micro powders) can be sampled and analyzed easily to assess physical or chemical properties. An example of this would be the analysis of particle size – primarily using a laser particle size analyzer.

Qingdao Decent Group‘s Rotary Sample Splitter

Many sample dividers are small devices, designed for splitting small samples.

Qingdao Decent Group manufactures a larger sample divider for the accurate division of bulk samples.

The samples are fed as a falling stream at a controlled rate. The samples are then collected in equal segments within a circle of segmental buckets. There are 8 segments in total, so the operator is able to collect up to 8 samples during a cycle.

The operator can turn the bucket by hand if needed, so each segment can be manually placed in front of the unit.

It is more than 99% accurate and meets all internationally recognized sampling protocols. SUS304 stainless steel is used for all parts of the machine that are in direct contact with the sample at any stage of the process.

One of the most important aspects of the process is ensuring the sample does not get contaminated. The sample splitter is completely sealed on the inside. A dust inlet is present for the mounting of a dust extraction pipe.

As a safety measure, the sample divider will not run while the lid is open.

This sample divider has two models available: DRSD16 and DRSD 40.

The specifications are a follows:

- DRSD16

Division Granularity: <13-3 mm

Division Rate: 1/2-1/8

Hopper Capacity: 16 kg

Bucket Capacity: 2 kg

Bucket Quantity: 8 pcs

Productivity: 1200-600 kg/h

Speed: 4-60 rpm

Power: 0.75 kW

Voltage: 3 ph, 380 V

Weight: 100 kg

Dimensions: 920 x 460 x 940 mm

- DRSD40

Division Granularity: <25-6 mm

Division Rate: 1/2-1/8

Hopper Capacity: 40 kg

Bucket Capacity: 50 kg

Bucket Quantity: 8 pcs

Productivity: 1800-1200 kg/h

Speed: 4-60 rpm

Power: 1.1 kW

Voltage: 3 ph, 380 V

Weight: 160 kg

Dimensions: 1300 x 620 x 1300 mm

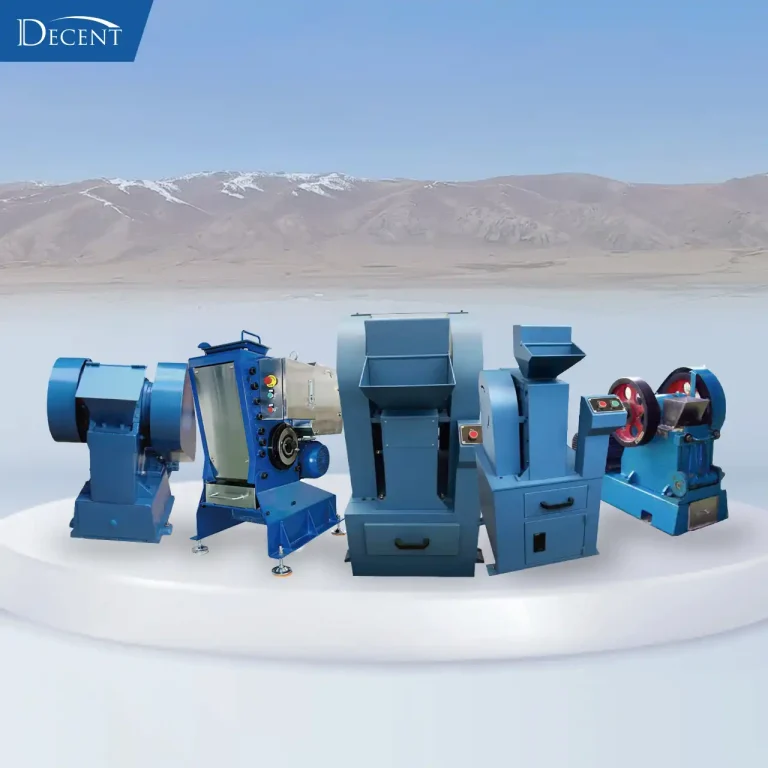

Other Plant Equipment

If you are a laboratory project manager, there may be other equipment beyond a rotary sample divider that you are in need of. Qingdao Decent Group manufactures a wide range of machinery for use in mineral laboratories, sample preparation, ore assay, and more.

We offer the following sampling and sample preparation equipment:

- Lab Jaw Crusher

- Hammer Crusher

- Laboratory Sample Pulverizer

- Standard Sieve Shaker

- Three Dimensional Mixer

- Drying Oven

- Pulverizing Bowls

These can all be used alongside the rotary sample divider for processing and analyzing samples.

Beyond this, we are also able to supply lab safety equipment, test and analysis equipment, fire assay equipment, and more.

The Right Equipment for You

There are a lot of options when it comes to laboratory and plant equipment. It can often be difficult to know exactly what you need.

Qingdao Decent Group is dedicated to producing high-quality equipment and ensuring our customers’ needs are met.

Our R&D team and Marketing & sales team each have over 20 years of experience, and our mineral specialist team has around 50 years. That is a lot of expertise, and we are always happy to use it to help our clients.

If you are interested in any of the equipment we have to offer, or just have some questions, don’t hesitate to contact us.