In today’s high-stakes mineral exploration landscape, where every sample holds potential millions in resource value, laboratory sample preparation has evolved from routine procedure to strategic advantage. The initial crushing stage is make-or-break for the entire sample preparation workflow—this first step directly shapes how homogeneous and representative your subsequent samples will be.

Yet in mining labs around the world, primary sample crushing still comes with a host of headaches: abrasive materials wear down equipment far too early, maintenance shutdowns delay critical analytical data, cross-contamination risks ruin sample integrity, and inconsistent particle sizes throw off the entire testing process.

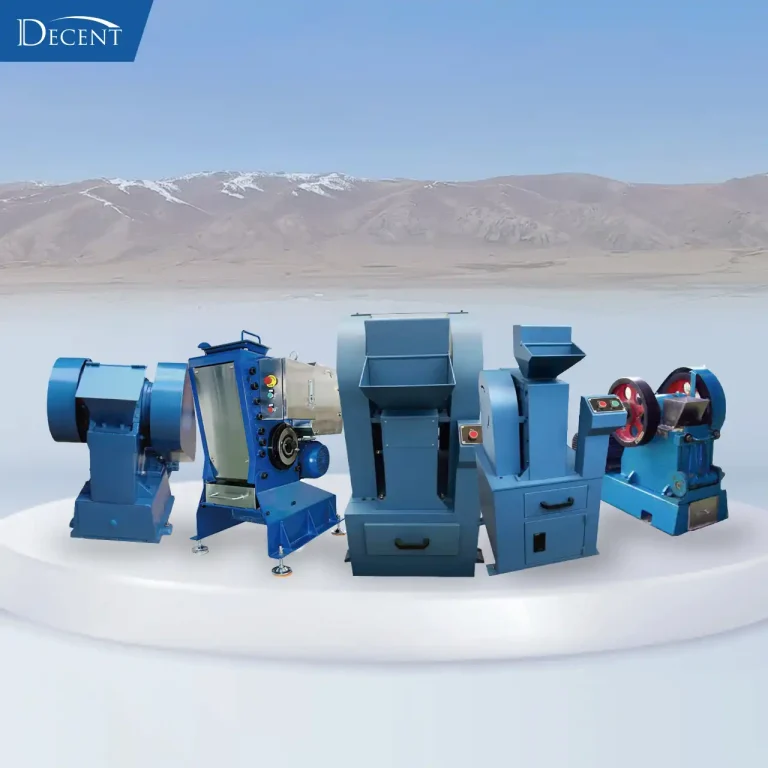

That’s where rugged lab jaw crushers step in as a game-changer for modern mineral labs. As a leading manufacturer of mineral laboratory equipment, Qingdao Decent Group offers a comprehensive lineup of 18 lab jaw crusher models—this versatile range is what sets us apart from the competition.

DECENT Comprehensive rugged lab jaw crusher Portfolio

With eighteen distinct models spanning laboratory-scale to pilot-plant capacity, DECENT rugged lab jaw crusher series represents over a decade of focused engineering refinement. Unlike generic industrial crushers repurposed for laboratory use, each DECENT model is purpose-built for mineralogical applications:

- Gold and precious metals analysis;

- hard rock strata;

- soft mineral processing;

- ultrafine preparation requirements

The DJC Series features our flagship laboratory units, while the heavy-duty models handle extreme sample hardness with remarkable efficiency. For specialized applications requiring absolute sample isolation, our models incorporate complete internal sealing systems that prevent even microscopic cross-contamination between samples.

This model diversity isn’t merely about capacity—it reflects DECENT’s deep understanding that mineral laboratories face vastly different operational realities, each demanding equipment engineered for their specific environmental and analytical challenges.

The Engineering Philosophy Behind DECENT Rugged Lab Jaw Crushers

Rugged and Durable for the Harshest Environments

Every DECENT jaw crusher is designed with durability, not cost-cutting, at its core, because we understand that superior performance is the key to success in the laboratory. The DJC series jaw crusher frame is constructed from solid steel and cast iron, capable of withstanding the wear and tear from continuous vibration. This construction eliminates stress points that typically lead to catastrophic failure in conventional units.

The crushing chamber itself employs replaceable manganese steel liners with proprietary geometry that maintains optimal nip angle throughout the wear cycle while ensuring consistent particle size distribution. Even the toggle plates feature sacrificial design elements that protect the main frame during accidental overloading events—preventing catastrophic damage that would otherwise require complete unit replacement.

Maintenance Minimization Through Intelligent Design

Laboratory managers often cite equipment downtime as a major operational concern and challenge. DECENT rugged lab jaw crusher series addresses this through:

- Quick-change jaw plate requiring no special tools—reducing liner replacement time from hours to minutes

- Modular drive components can be serviced independently—no need to take apart the entire system. This cuts down on maintenance hassle and saves time.

- Heavy-duty, easy-to-remove hopper designed for simple disassembly and upkeep, it minimizes the risk of cross-contamination between samples.

A high-performance jaw crusher doesn’t just boost the efficiency of initial laboratory sample crushing—it also keeps maintenance needs low, drastically reducing unplanned downtime for labs. Field data from our global projects show that our maintenance requirements are significantly lower compared to similar systems—a crucial advantage for remote laboratories where on-site technician support requires complex logistical support.

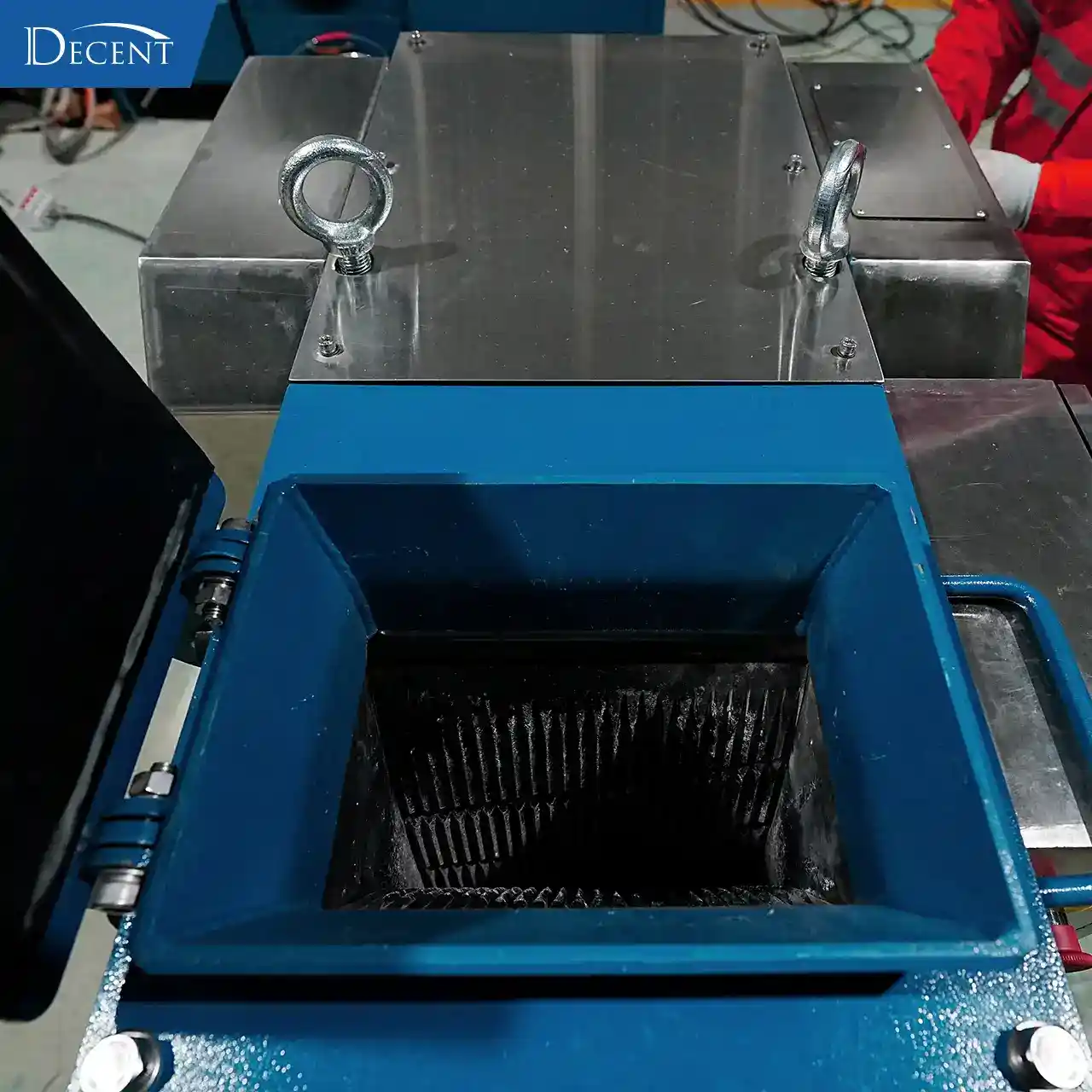

Complete Sealing for Sample Integrity

Sample contamination is another major factor hindering laboratory analysis. DECENT rugged lab jaw crusher employs multiple sealing protections within its crushing chamber to control cross-contamination of samples.

- External dust barrier prevents the entry of environmental particles;

- The crushing chamber is completely sealed during equipment operation to prevent splashing and dust generated during crushing from escaping;

- A discharge box at the bottom of the equipment centrally collects the crushed sample, providing a separate space to reduce contamination.

This sealed design ensures that high-value samples (especially suitable for gold exploration, rare earth element analysis, or environmental compliance testing) maintain absolute integrity throughout the entire processing.

Where DECENT Rugged Lab Jaw Crushers Deliver Critical Performance

Rare Earth Element Processing (Malaysia, 2024)

(https://www.decent-group.com/malaysia-container-laboratory-project-2024/)

For a client with strict requirements to completely prevent cross-contamination between different rare earth mineral batches, our rugged lab jaw crushers won full recognition thanks to their robust, durable housing and fully enclosed working chamber. Once the full sample preparation lab was up and running, these high-efficiency, low-maintenance jaw crushers delivered exceptional throughput during the critical primary crushing stage—exactly what the client needed for their strict rare earth processing requirements.

Sample Preparation in Extremely Cold Regions (Canada, 2022)

(https://www.decent-group.com/canada-extreme-cold-resistant-container-laboratory-project-in-2022/)

We supplied the client with a complete containerized sample preparation lab, engineered to operate in brutal -50°C frigid conditions. Equipped with two DJC-series rugged lab jaw crushers inside, the lab was engineered for sustainable sample crushing. While conventional crushers ceased operation due to thermal contraction, DECENT crushers integrated seamlessly into the containerized laboratory system, playing a critical role in the key sample analysis process.

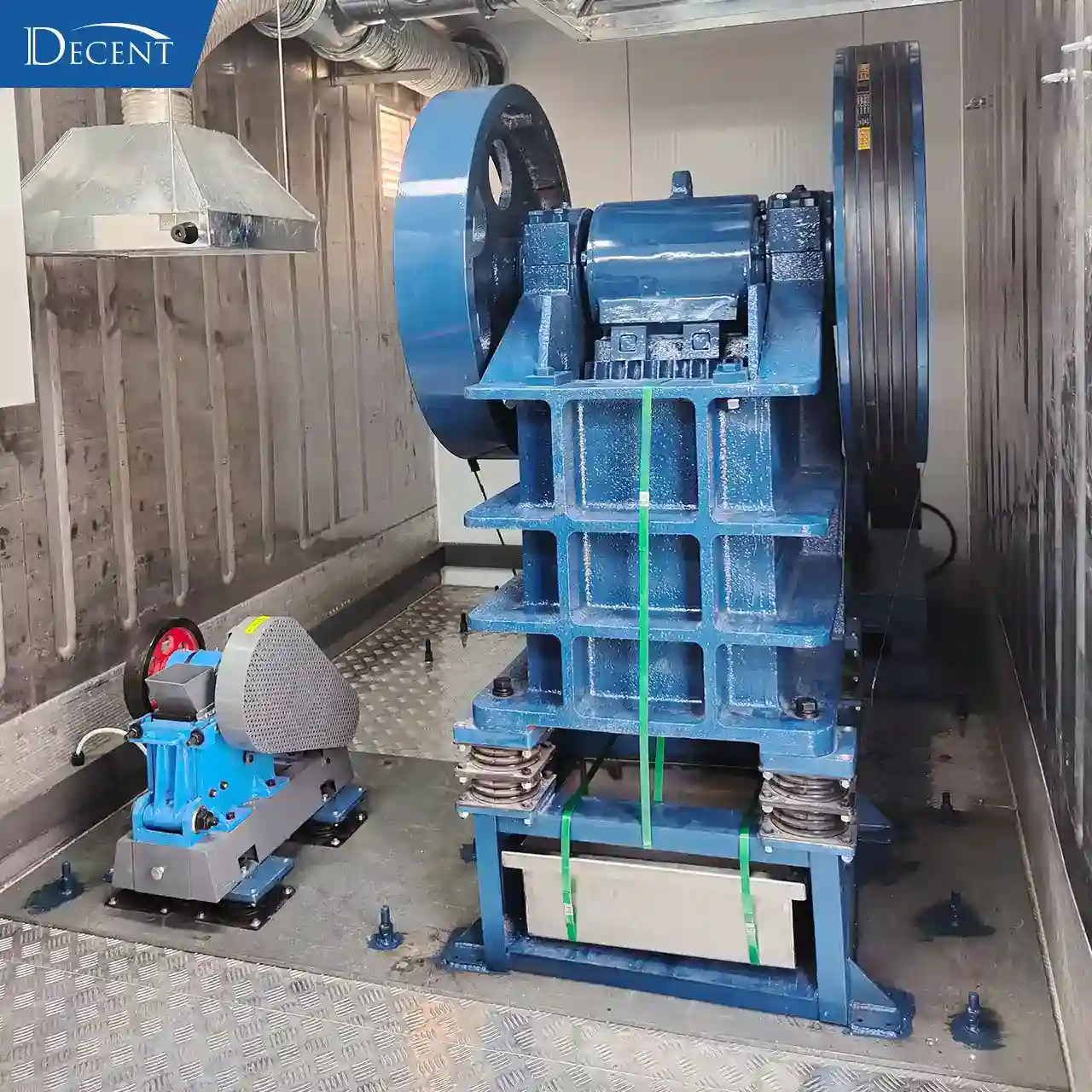

Industrial-Grade Primary Crushing Project (China, 2022)

(https://www.decent-group.com/bv-china-container-laboratory-project-in-2022/)

To meet a client’s need for high-volume sample processing, we integrated a 2.5-ton jaw crusher into a containerized laboratory setup. To avoid disruptions to other precision equipment caused by machine operation, the DECENT team pioneered a customized shock absorption system. This system effectively isolated heavy vibrations generated during crusher operation, perfectly fulfilling the client’s requirements for efficient crushing of large-flux samples.

The Future of Laboratory Sample Preparation: Durability and High Efficiency

In today’s fast-paced strategic resource exploration environment, the importance of mineral laboratories is increasingly evident. Providing faster and more accurate analysis under limited resources has become essential. Similarly, equipment reliability has shifted from an operational issue to a strategic necessity. Qingdao Decent Group’s rugged lab jaw crusher series (https://www.decent-group.com/product/lab-jaw-crusher/)embodies this reality—not as a collection of machines, but as integrated analytical guardians that protect data integrity from the very first processing step.

Looking forward, our engineering team continues advancing the boundaries of laboratory crushing technology. Through every innovation, one principle remains unchanged: in the unforgiving world of mineral analysis, true value lies not in initial purchase price, but in decade-long operational excellence.

When your laboratory’s reputation depends on every sample, every analysis, and every decision—settle for nothing less than equipment engineered to endure.

Ready to fortify your sample prep workflow?