Rotary Sample Divider accurately dispenses large quantities of samples

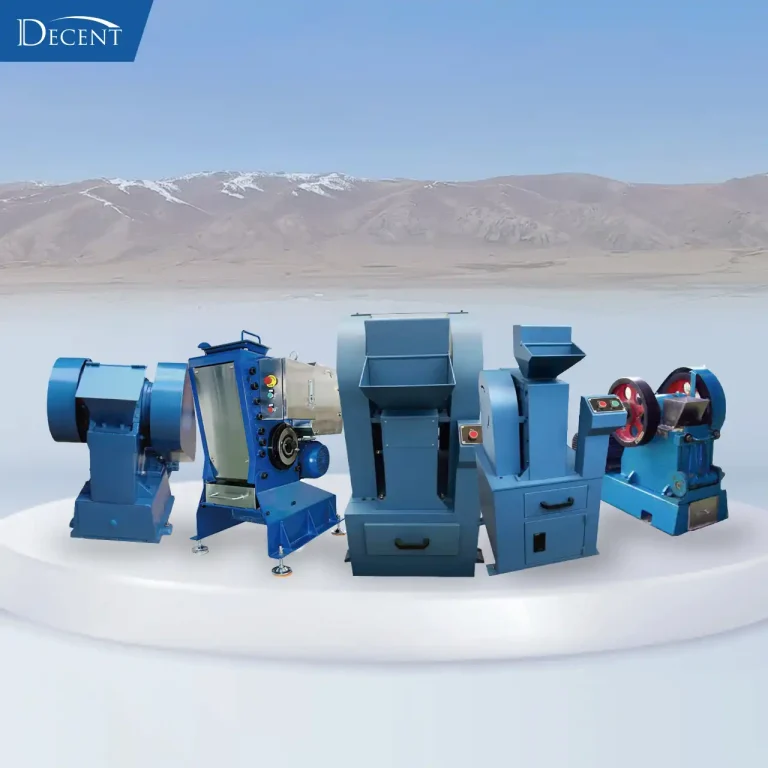

This is the rotary shrinking machine produced and manufactured by Qingdao Decent Group.

It can accurately divide a large number of laboratory samples into equally representative samples, inject the samples in a uniform feeding, free-falling manner, and divide the samples at a constant speed.

The laboratory operator pours the sample into the feed inlet, and the sample descends at a controlled rate into the eight segmented buckets below which are always rotating at a constant speed.

In this way, the sample is quickly divided into 8 equal parts in a very short time, and the representativeness of the sample is greater than 99%.

In order to achieve specifications, the rotary reducer consistently operates in accordance with internationally recognized sampling protocols.

You can clearly see in the video that the feed port of our rotary reducer and all the parts that are in direct contact with the sample are made of SU304 stainless steel without stacking materials; the 8 rotating barrels below are used for sample division and collection , each barrel is equipped with a handle for easy disassembly and access.

The traditional manual reduction has large errors and low efficiency; while the rotary reduction machine can process a large number of samples in a short time, and can also avoid manual errors, which can be described as a good helper to improve laboratory efficiency in the process of sampling and preparation.

The vibration frequency, rotation speed and reduction time of the rotary reduction machine can be adjusted and set.

In addition, our rotary reducer is equipped with a safety switch inside, which can prevent misoperation when the cover is opened and protect the safety of the operator. If required, we can also customize according to customer’s requirements.