Introduction: The Critical Dilemma in Mineral Analysis

In high-stakes fields like mineral assaying and mining, accuracy isn’t just important—it’s non-negotiable. And when you’re running a commercial gold or platinum testing lab against tight deadlines, time truly is money.

At the heart of this race against the clock sits a deceptively simple component: the fire assay crucible. These special refractory containers need to be able to reliably withstand temperatures exceeding 1000°C for several hours, resisting thermal shock and chemical corrosion, thereby enabling the precise recovery of precious metals.

This requirement presents a significant challenge to laboratory operators worldwide: how to strike a balance between quality and cost?

The choice felt binary:

→ Premium crucibles meant higher investment but minimal re-runs and unwavering reliability.

→ Budget alternatives promised savings but carried hidden costs.

Traditionally, laboratory operators faced a binary choice: invest in premium, high-cost crucibles to ensure reliability and minimize re-runs, or opt for budget alternatives that carry significant operational risks of failure, sample loss, and heavy financial losses. A sudden failure—whether it’s a crack, a stuck lead button, or inconsistent dimensions—can bring production to a halt, skew results, and lead to costs that far outweigh the initial savings from choosing cheaper crucibles.

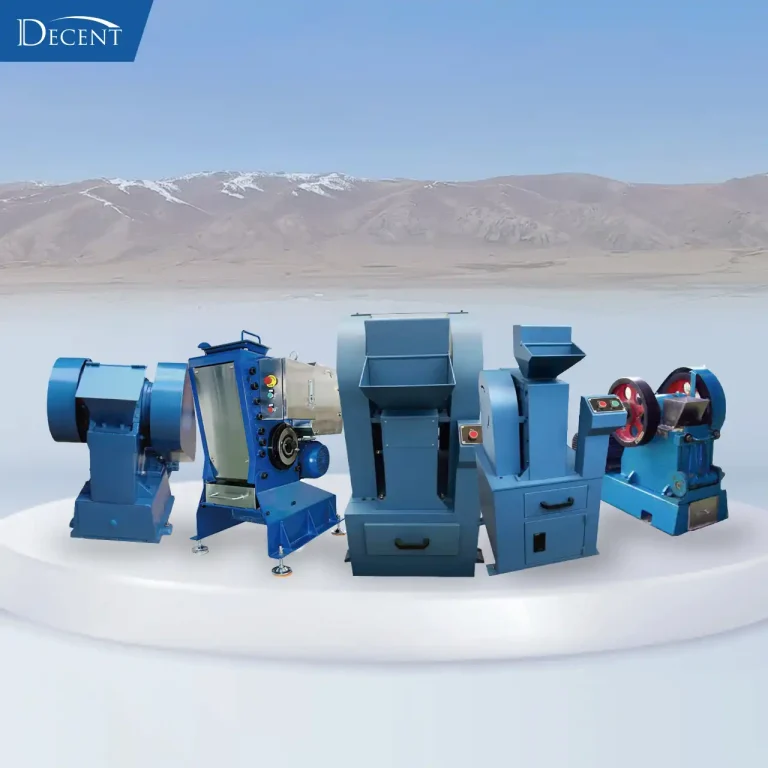

Qingdao Decent Group, specializing in mineral laboratory systems, aims to bridge this gap. Leveraging its proprietary materials science innovations and advanced manufacturing capabilities, DECENT has established itself as a key supplier in the field. The company supplies fire assay crucibles designed to maintain high precision while offering improved economic value through extended service life.

|

|

The Anatomy of Risk: Why Quality is Essential

A fire assay crucible isn’t just a simple container—it’s the core of the gold and silver analysis process. In the traditional fire assay method, the fusion stage is absolutely key: you take a ground-up sample, mix it with fluxes like litharge (that’s lead oxide), borax, and soda ash, then heat this mixture intensely inside the crucible. Typically, the temperature ranges between 850°C and 1060°C.

This heat melts the mixture, and the molten lead then collects the precious metals, forming a dense “lead button.” At the same time, the unwanted rock—we call that gangue—turns into a lightweight, discardable slag that floats right on top of the molten mix.

But if the crucible fails during this crucial one-hour fusion period, the consequences hit fast and hard:

- Production halts: A cracked or leaking crucible means you have to shut down the furnace, do time-consuming cleanup, and replace the crucible—all of which directly cuts into how many samples you can process (that’s your sample throughput).

- Compromised results: Sometimes the molten lead button sticks to the crucible wall—we call this “sticking.” When that happens, it makes complete precious metal recovery impossible, corrupting final assays.

- Hidden costs multiply: Each failed assay demands complete reprocessing. That uses up more labor, energy, flux, and time—and it wipes out any supposed cost savings you might have gotten from buying a cheaper crucible in the first place.

For commercial labs that process high volumes of samples, cutting down on these risks is top priority. In this environment, crucible quality isn’t a cost center; it’s insurance against operational catastrophe.

Global Trends: The Triple Pressure Point

Today’s mineral analysis landscape is being reshaped by three converging forces, all amplifying demand for superior crucibles:

- The Efficiency Imperative

With declining ore grades and volatile commodity prices, mining companies demand maximum throughput from every operational dollar—including their labs. As one industry veteran puts it: “When your average sample contains less than 2 grams of gold per ton, every assay must count.” This reality makes consistent crucible performance non-negotiable—dimensional variations or premature failures directly erode profitability. - Waste Reduction and Resource Efficiency

Environmental responsibility has become a defining corporate mandate. Laboratories are actively seeking consumables with a longer operational lifespan to reduce their consumption footprint. Take clay fire assay crucibles—such as those developed by DECENT, for example. These products are purpose-built to withstand 5 or more usage cycles, and this extended service life brings tangible benefits: it significantly cuts down on the quantity of consumables that need to be procured, which in turn eases procurement complexity, reduces freight expenses, and minimizes waste production. All of these advantages directly support an organization’s sustainability targets.

- Automation and Integration

The industry’s increasing requirement for laboratory automation necessitates strict quality control from suppliers. Automated systems rely heavily on robotics for precise handling. Even minor inconsistencies in crucible dimensions, weight, or base diameter can lead to mechanical jams, stopping automated sequences and causing significant downtime. Manufacturing processes must ensure stringent tolerance control, placing increased value on suppliers.

Engineering Performance: Defining the Superior Crucible

The ability of a crucible to meet these demanding operational and commercial requirements hinges entirely on its technical characteristics and material composition. we’ve identified five non-negotiable performance characteristics:

High Refractoriness

Refractoriness is fundamental for crucibles. A good one must handle extremely high furnace temps—ideally up to 1350℃—without deforming, softening, or breaking down structurally. This heat stability directly lets it keep its shape and work well long-term.

Excellent Thermal Shock Resistance

Crucible use often involves rapid heating/cooling (e.g., during pouring). So excellent thermal shock resistance is key: it needs to handle these frequent temp changes without cracking. This not only prolongs service life (for repeated use) but also keeps operations safe—cracks could cause leaks or equipment damage.

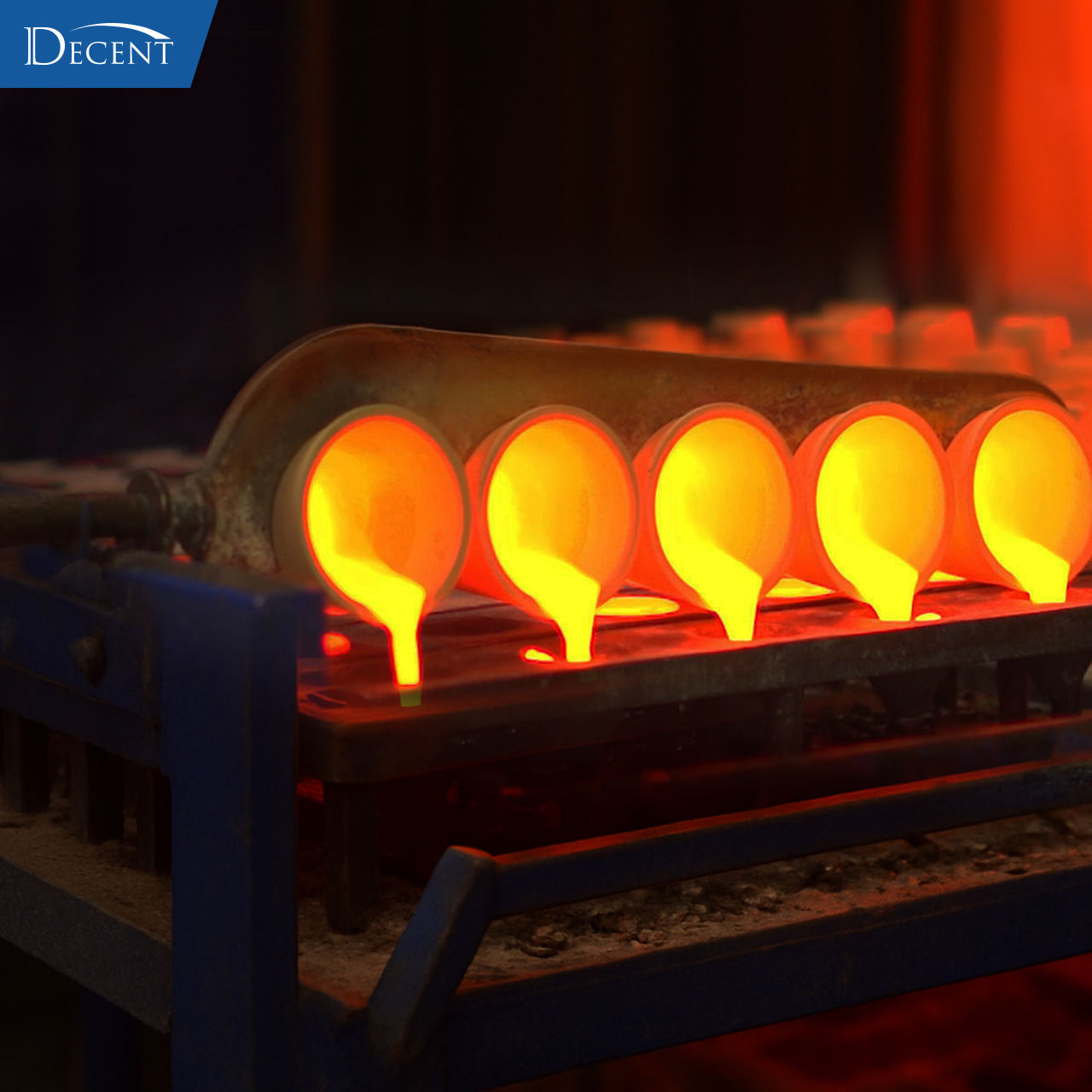

This image captures a batch of newly fired clay crucibles, manufactured by Qingdao Decent Group, emerging from the kiln at the factory. |  Qingdao Decent Group’s pre-kiln crucible storage ensures uniform quality before high-temperature firing. |

High Mechanical Strength

Crucibles face physical impacts during handling, furnace loading, and unloading. A quality crucible needs a dense, strong structure to resist this. Enough mechanical strength prevents accidental breakage that could disrupt production or raise safety risks.

Exceptional Chemical Stability

Metallurgical processes use corrosive fluxes and molten slag that react with crucible materials over time. To avoid wearing out, a good crucible must resist this corrosion. This stops erosion (which shortens its life) and prevents contaminating the molten contents inside.

Non-Wetting Properties

The inner wall must allow molten lead buttons to separate cleanly from slag. This seemingly simple property determines whether precious metals fully recover or remain trapped in ceramic pores.

DECENT precision manufacturing starts with an in-depth mastery of the ceramic material composition.

DECENT’s proprietary formulation delivers this performance through precise chemistry: 60-65% silica (SiO₂) and 30-34% alumina (Al₂O₃), with impurities like iron oxide (Fe₂O₃) and sodium oxide (Na₂O) held to minimal levels (≤2% and ≤0.1% respectively). This exacting composition prevents assay interference while maximizing service life.

DECENT Manufacturing Mastery: Control from the Source

Qingdao Decent Group’s ability to successfully bridge the quality-cost gap stems from a vertical integration strategy: controlling the quality of the clay crucible from the raw material source through final inspection.

Precision Production and Quality Control

We’ve engineered our manufacturing process for consistent quality—critical for automated labs. Here’s the streamlined workflow:

- Raw Material Preparation

We handpick high-purity fire clay and kaolin, then precision ball-mill to exact particle sizes. Balancing coarse particles (strength) and fine particles (density) delivers exceptional thermal shock resistance—our refined blend meets lab rigor.

- Forming

The homogenized mixture is shaped via curing and precision stamping. High-pressure equipment creates dense, robust crucibles with tight dimensional consistency across batches—ensuring seamless integration with automated systems.

- Drying and Firing

Formed crucibles undergo controlled slow drying to remove moisture and prevent cracks. Sintered in high-temperature kilns with precisely calibrated profiles: gradual heating, targeted hold times, slow cooling—guaranteeing durability and chemical stability.

A close-up of the specialized clay mixing process at the Qingdao Decent Group factory. |  Precision in production: Semi-automated tools at the DECENT factory are used for the consistent and accurate shaping of fire assay clay crucibles. |  High-temperature kilns with precision-calibrated profiles to ensure unmatched durability and chemical stability for fire assay crucibles in metallurgical labs. |

The Inspection Protocol

Rigorous manual inspections occur at every critical stage. Technicians visually check for cracks, defects, and contaminants, while verifying key dimensions (wall thickness, height, diameter) against strict tolerance standards. This uncompromising control ensures flawless performance in modern robotic labs’ high-precision loading/unloading.

The Acid Test: Performance Validation and Proof

The ultimate measure of a crucible is not its appearance, but its performance under simulated operational stress. DECENT’s commitment to quality is validated through rigorous, in-house usage testing designed to mirror the harshest conditions a crucible might face.

For performance validation, randomly selected crucibles are subjected to simulated fire assay conditions:

- A sample and an aggressive flux (often formulated without silica sand to increase the chemical attack) are added.

- The crucibles are placed in a fusion furnace at a typical operating temperature, such as 1050℃ for a specified time.

- This process is repeated multiple times—typically five times or more—to test the material’s fatigue and endurance.

Pass Criteria for this rigorous test are uncompromising: the crucible must show no structural damage (cracks or holes), exhibit consistent pouring characteristics without lead splashing, and ensure the clean, complete separation of the lead button from the slag.

This level of R&D and quality control translates directly to the customer’s bottom line: DECENT crucibles leading to the highly valued performance indicators of a significantly extended lifespan and lower cracking and sticking rates.

A cross-sectional cut of a DECENT clay crucible is used to verify wall thickness and dimensional consistency for reliable fire assay results. |  Qingdao Decent Group’s clay crucibles withstand 5+ firings without degradation, maintaining material integrity under repeated thermal stress. |

Conclusion: The True Economic Advantage

While DECENT, as one of China’s premier fire assay crucible suppliers with highly efficient large-scale manufacturing and a streamlined global supply chain, can offer competitive unit pricing, the true economic gain for the client comes from efficiency:

By leading to fewer re-assays and lasting significantly longer, the initial investment in a high-quality DECENT crucible is swiftly offset by savings in labor costs, energy consumption, and freight expenses.

The challenge of balancing precision and profitability in the assay laboratory no longer requires compromise. Through persistent R&D, advanced manufacturing controls, and a commitment to total cost of ownership driven value, Qingdao Decent Group has conclusively proven that superior quality and economic cost-efficiency are not mutually exclusive.

DECENT’s fire assay crucibles offer the consistent, extended-life performance required for high-precision assay results, while the company’s efficient global operation maintains highly competitive pricing. By choosing a partner who understands the intricacies of the entire mineral laboratory system, organizations can simultaneously improve sustainability, decrease operational risk, and significantly increase throughput.