·Industrial-grade compatibility with multipour/multiload systems boosts efficiency

·User-friendly design simplifies maintenance and operation

·Precise temperature control ensures consistent heating

·Safety features include electronic protection and hands-free pneumatic doors

·Energy-efficient and environmentally friendly design

·Durable heating elements and easy consumable replacement

·Customization is available

A Fire Assay Fusion Furnace (often simply called a fusion furnace or assay furnace) is a specialized high-temperature furnace used in the fire assay method to melt or “fuse” ore or concentrate samples with a flux mixture. This process allows the precious metals (like gold and silver) within the sample to collect into a lead button, separating them from the bulk of the sample’s matrix.

The fire assay process is a fundamental and time-honored technique in the mining and metallurgical industries, used to accurately determine the concentration of precious metals such as gold, silver, and platinum group elements (PGEs) in various ore samples and metallurgical products.

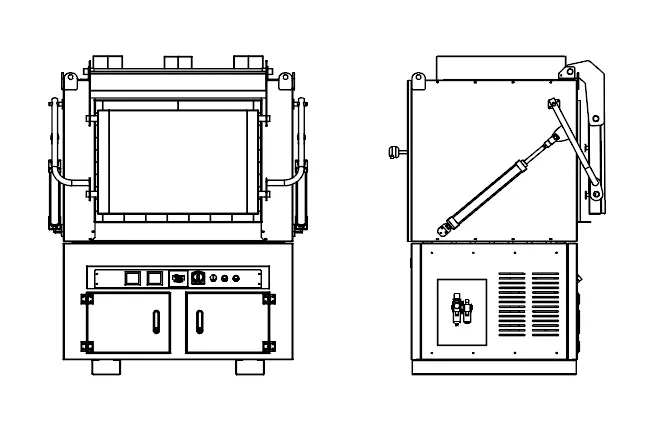

DECENT Fire Assay Fusion Furnace is essential for laboratories conducting precious metal analysis. It melts crushed ore samples mixed with fluxes in refractory clay crucibles. The industrial-sized furnaces have spacious chambers that can hold multiple crucibles simultaneously, enhancing laboratory efficiency and reducing manual operations. DECENT fusion furnaces are equipped with an advanced automatic temperature control system that ensures uniform and stable high temperatures, reaching up to 1200°C. This precise thermal management is crucial for the reliability of the fire assay process and the accuracy of analytical results.

·Durable frame of 2mm galvanized steel with electrostatic paint resists corrosion.

·Furnace door with alumina and aluminum silicate offers excellent insulation.

·Silicon carbide heating elements provide chamber uniform heat and long life.

·Independent muffle and plate design simplifies consumable replacement.

·Pneumatic door operated by foot pedal for hands-free convenience.

·K-type thermocouple and electronic controller ensure precise heating up to 1200°C.

| Model | Muffle No. | Working Area (WxDxH) | Crucibles Loading | Controler | Heating Element | Door Opening Method | Air Compressor Recommended Air Pressure | Rated Temperature | Power | Dimension (WxDxH) |

| (mm) | (Qty x Size) | (MPa) | (℃) | (kW) | (mm) | |||||

| DE1220FF | No. 3 | 370*450*220 | 12x50g/65g 15x/40g/55g 20x30g | Transformer 3ph, 20kVA | Silicon Carbide Element | Pneumatic | 0.4-0.5 | 1200 | 11-18 | 1137*1041*1654 |

| DE2030FF | No. 6 | 470*570*220 | 20x50g/65g 30x30g/40g/55g | Transformer 3ph, 25kVA | Silicon Carbide Element | Pneumatic | 17-23 | 1237*1133*1654 | ||

| DE2536FF | No. 7 | 590*560*210 | 25x50g/65g 36x30g/40g/55g | Transformer 3ph, 30kVA | Silicon Carbide Element | Pneumatic | 17-28 | 1367*1131*1686 | ||

| DE3042FF | No. 9 | 670*650*255 | 30x50g/65g 42x30g/40g/55g | Transformer 3ph, 30kVA | Silicon Carbide Element | Pneumatic | 17-28 | – |

To find out more about our products and solutions, please fil out the form below and one of our experts wil get back to you shortly.