In demanding industrial applications such as fire assay, heat treatment, sintering, and specialized ceramic firing, the ability of a furnace to consistently withstand extreme temperatures and corrosive environments is paramount. The integrity of the furnace chamber directly impacts energy efficiency, process stability, and the overall lifespan of the equipment. Traditional furnace linings often struggle under continuous thermal stress, leading to frequent maintenance, reduced productivity, and compromised product quality.

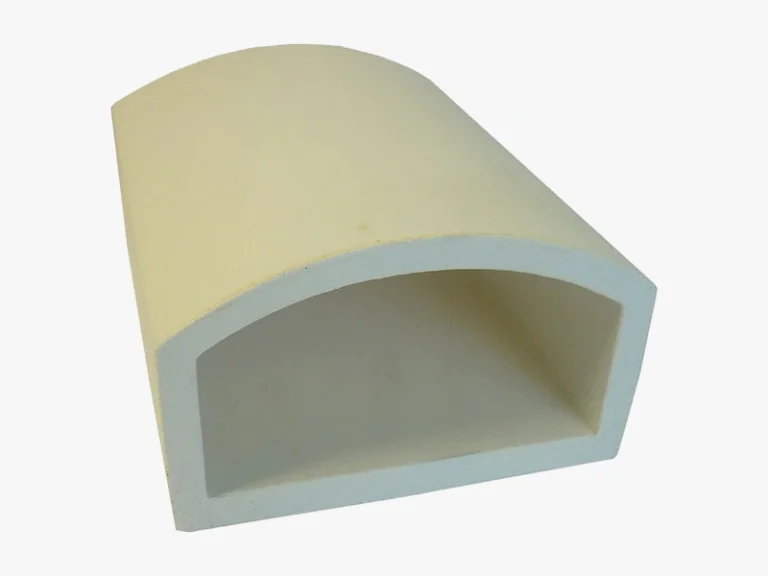

The DECENT Furnace Refractory Chamber offers an advanced, robust solution to these challenges. Designed from high-performance silicon carbide (SiC) raw materials, these chambers and their interlocking tiles are engineered to provide superior thermal properties and mechanical strength, ensuring reliable operation even in the most aggressive high-temperature settings. They are an indispensable foundation for any operation requiring precise and sustained heat.

The DECENT Furnace Refractory Chamber stands as a testament to cutting-edge material science, delivering exceptional performance where other materials fail. Its construction from silicon carbide grants it remarkable thermal conductivity, allowing for efficient heat transfer and uniform temperature distribution within the furnace. Crucially, these components exhibit stable thermal shock resistance, meaning they can endure rapid heating and cooling cycles without cracking or degradation, significantly extending operational life.

Furthermore, their inherent corrosion resistance protects against aggressive chemical environments often encountered in high-temperature processes, safeguarding your investment. Available in various modular shapes like horseshoe furnace tubes, electric furnace tile plates, and guide rails, DECENT’s Furnace Refractory Chamber solutions are designed for easy removal and replacement. This modularity reduces maintenance time and costs, directly contributing to increased operational efficiency and long-term cost savings in diverse applications, from muffle furnaces to large-span kilns.

| Sic | >70%-85% | >90%-95% |

| FE2O3 | <1.0 | <1.0 |

| Density | >2.3-2.5 g/cm3 | >2.6-2.8 g/cm3 |

| Room Temperature Pressure | >40-60 Mpa | >70-80 Mpa |

| Shrinkage after Reheating | <0.5% | <0.1% |

| 0.2Mpa Load Softening Temperature | 1500°C | 1550°C |

| Product | Model | Sizes (mm) | Match Furnaces | Tile Size (mm) | Plywood Package (mm) |

| Chamber | 4 | 300x480x245 | DE50CF DE50CF01 | 450X250X15 | 700X600X430 660X400X390 |

| Vent | 4 | 265x65x200 | |||

| Chamber | 5 | 535x610x350 | DE100CF DE100CF01 | 560X480X25 | 720X435X800 |

| Vent | 5 | 475x75x250 | |||

| Chamber | 7 | 660x610x360 | DE25FF DE25FF01 | 590X560X25 | 840X440X800 |

| Vent | 6/7 | Φ100/Φ50×380 |

To find out more about our products and solutions, please fil out the form below and one of our experts wil get back to you shortly.