The automated fire assay system by Qingdao Decent Group integrates complex traditional fire assay processes into a highly efficient, precise all-in-one solution through seamless intelligent connection of robotic arms and orbital conveying systems.

Featuring our exclusive patented cupellation structure, it automatically identifies the cupellation endpoint of all cupels and retrieves them individually upon completion, effectively avoiding silver loss. Ideal for precious metal smelting, mineral testing, and related fields, the system supports modular standalone operation or full-line linkage, delivering exceptional flexibility and efficiency.

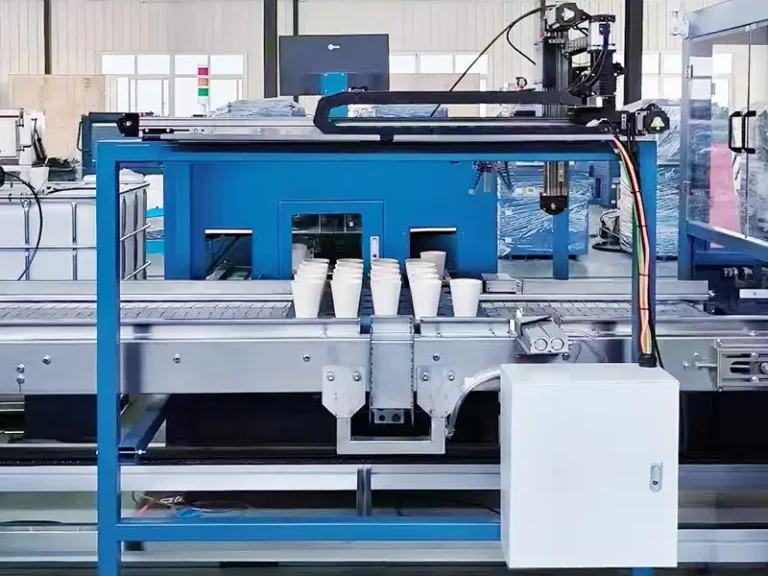

Receives process formulas via upper computer upon robotic arm crucible placement. Uses rotating silos and weighing modules for sequential feeding, then conveys crucibles to the next station.

Receives crucible trays via conveyor; after photoelectric positioning, films secure trays for reciprocating inversion mixing.

Utilizes screw quantitative injection for precise and uniform addition of covering agent to ore samples.

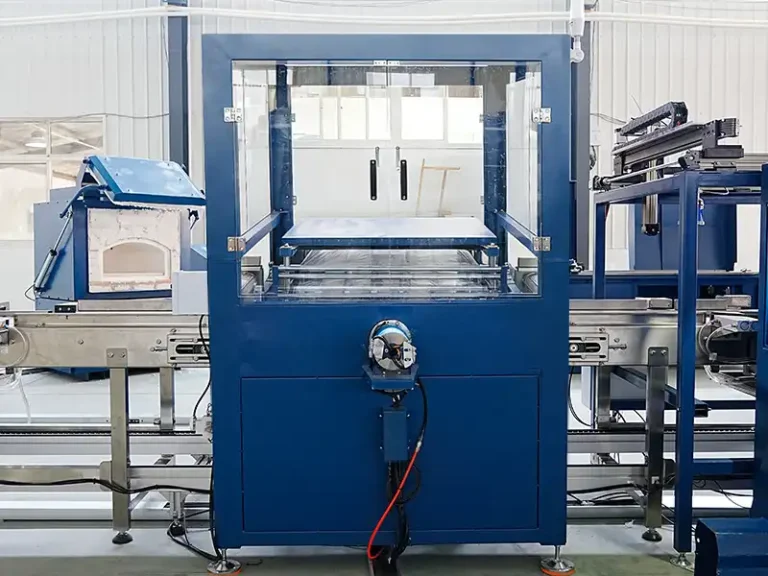

Robotic arm places crucibles into the furnace, achieving complete ore melting at 1200℃ in 70 mins.

The robotic arm pours the molten sample into the steel mold, which then automatically inverts to transfer the slag and lead button into the lead button tray.

Cupels enter modular chambers; endoscopes detect cupellation endpoints and retrieve finished cupels individually.

Precisely handles crucible grabbing, molten sample pouring, and waste crucible disposal.

| QINGDAO DECENT GROUP automated-fire-assay-system-brochure | en | Download |

To find out more about our products and solutions, please fil out the form below and one of our experts wil get back to you shortly.