In many industrial and laboratory settings, standard crushing methods fall short when materials require highly uniform, fine particle sizes or when dealing with challenging properties such as fibrous structures, high moisture content, or softness. Conventional crushers often produce an inconsistent product, generate excessive dust, or struggle with clogging when confronted with these specific material characteristics.

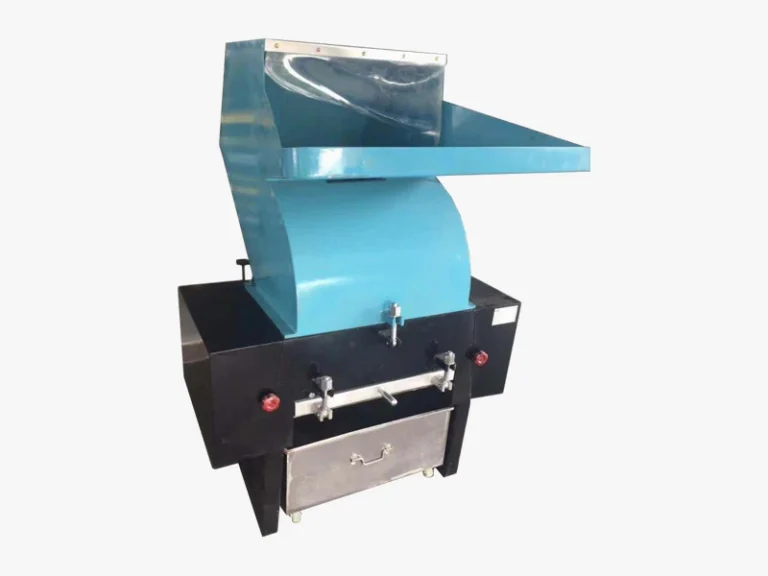

The DECENT Angle Cutting Crusher is an advanced solution meticulously engineered to overcome these limitations. Unlike impact or compression-based crushers, this specialized machine employs a precise cutting and shearing action, driven by high-speed rotation. This unique mechanism allows it to efficiently process a wide array of problematic materials, transforming them into a consistent and desirable fine output, making it an invaluable asset for analytical sample preparation, quality control, and various industrial applications where particle precision is paramount.

The DECENT Angle Cutting Crusher is designed for superior performance and user convenience, offering a targeted approach to material size reduction. Its core lies in a carefully optimized internal structure featuring robust, sharp cutting blades that work in conjunction with a precise screening system. This enables the machine to deliver exceptionally uniform particle sizes, crucial for accurate downstream analysis or production processes. Capable of handling various medium-hard and weakly abrasive materials, including those with elevated moisture levels, it prevents common issues like material loss or blockages often encountered with traditional crushers.

Furthermore, the Angle Cutting Crusher is built with a fully sealed cabinet and often includes an integrated dust suction device, significantly reducing airborne particulate matter and promoting a cleaner, safer working environment. With its low noise operation and features facilitating easy maintenance, this crusher provides a reliable and efficient solution for achieving fine granularity with unmatched precision.

| Model No. | Inlet Size | Productivity | Power | Overall Size | Net Weight |

| DACC150 | 160x150mm | 50-100kg | 2.2kW | 550x430x930mm | 165kg |

| DACC250 | 250x200mm | 100-200kg | 4kW | 830x560x1120mm | 270kg |

| DACC300 | 300x250mm | 150-300kg | 5.5kW | 830x560x1120mm | 380kg |

| DACC380 | 380x250mm | 200-400kg | 7.5kW | 810x960x1280mm | 580kg |

| DACC500 | 500x290mm | 350-600kg | 11kW | 1350x1000x1500mm | 850kg |

| DACC600 | 600x350mm | 800-1500kg | 15kW | 1450x1100x1600mm | 950kg |

| DACC700 | 700x490mm | 1000-2500kg | 22kW | 1800x1430x1750mm | 1500kg |

To find out more about our products and solutions, please fil out the form below and one of our experts wil get back to you shortly.