Mobile Mineral Processing Lab Revolutionizes East Africa: A mining company in Djibouti recently received a powerful tool. Qingdao Decent Group’s mobile sample preparation laboratory arrived at its destination after a long journey. The mobile mineral processing lab integrates mineral sample processing equipment into a standard 20-foot shipping container. This solution can be quickly operational upon arrival, addressing the customer’s pain point of efficient and timely analysis at remote mining sites.

Djibouti, a microcosm of East Africa, is increasingly becoming a strategic location for mineral exploration, owing to its rich mineral resources. With the region’s growing status, there is an urgent need for efficient, on-site mineral analysis solutions to help mining companies make critical decisions and drive the development of the East African mining industry. This Mobile Mineral Processing Lab directly addresses that demand.

East Africa’s Mining Boom Demands On-Site Solutions

Djibouti has long been known as East Africa’s fortress, serving as a strategic link between Ethiopia, Eritrea, and global trade routes. With the booming mining sector, Djibouti, leveraging its abundant mineral resources and strategic location, is contributing to mineral exploration efforts. Traditional lab infrastructure is often unavailable or impractical in remote zones. Mobile labs bridge this gap—bringing the lab to the mine, not the other way around.

According to the World Bank’s 2024 Africa Mining Vision report, decentralized processing units are key to reducing analysis turnaround time by up to 70% in frontier regions—a game-changer for project economics.

A Complete Mobile Mineral Processing Lab in 20 Feet

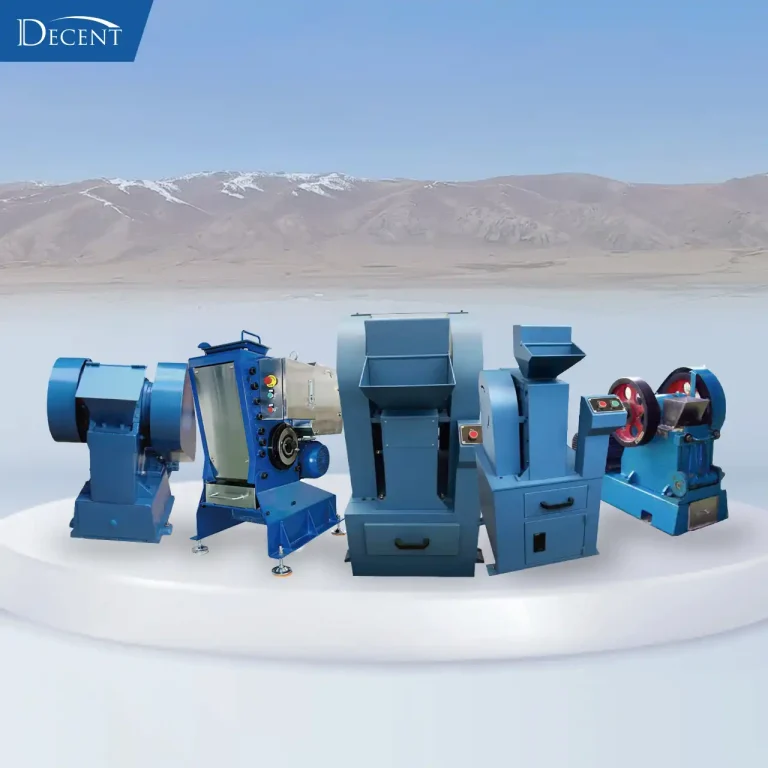

Qingdao Decent Group engineered this Mobile Mineral Processing Lab around three pillars: mobility, precision, and efficiency. The laboratory is divided into two areas based on functional requirements:

- Sample Processing Area: Equipped with a DECENT large-capacity electric oven, a robust jaw crusher, and a pulverizer mill, it is primarily used for pre-processing mineral samples. Each piece of equipment is connected to ventilation ducts and filtered and purified by a pulsed dust collector to ensure a safe laboratory environment.

- Weighing Area: A dedicated weighing area is physically isolated from the sample handling area to prevent sample contamination. Dust-free operation by staff helps prevent contamination of samples.

The layout uses intelligent spatial partitioning to prevent cross-contamination while maximizing workflow efficiency—proving that small spaces can deliver big results.

See the full specs of the DECENT Containerized Mobile Mineral Processing Lab .

DECENT Equipment: Built for Harsh, Remote Conditions

Every component inside the container is a DECENT-branded system, selected for durability and performance in high-dust, high-temperature environments typical of East African mining sites.

- Large-Capacity Electric Oven utilizes forced air cooling technology to ensure rapid and uniform drying. It’s suitable for drying large samples, significantly reducing drying time.

- DECENT Jaw Crusher is designed specifically for the primary crushing of mineral samples, achieving a high crushing ratio.

- The DECENT dual-vial mill allows two samples to be processed simultaneously. This boosts overall throughput and enables parallel workflows based on customer needs, maximizing the lab’s utilization.

The reliability of the DECENT equipment ensures consistent performance, a non-negotiable requirement for high-stakes mineral exploration.

Rapid Deployment, Immediate Impact

Unlike traditional labs that take months to construct, this Mobile Mineral Processing Lab was factory-assembled, tested, shipped, and operational within six weeks of order confirmation. Once on-site in Djibouti, it required only power and leveling to begin processing samples.

The client reported that sample-to-analysis time dropped from 10 days to under 48 hours—dramatically accelerating exploration decision cycles.

“This isn’t just a lab—it’s a force multiplier for our field teams,” said the project manager at the Djiboutian mining services firm.

Strengthening Local Capacity, Supporting Regional Growth

The deployment of this mobile Mobile Mineral Processing Lab brings multiple tangible advantages to the Djiboutian client and the wider regional mining industry:

- Container labs, with their portability, can be quickly transported and deployed wherever needed, especially in remote mining areas, saving mining companies significant costs.

- Container labs can be deployed directly at the mining site and, provided the infrastructure is in place, can be quickly deployed and used, facilitating real-time on-site analysis.

- The fully-equipped lab allows local teams to operate using modern, standardized procedures. This raises the overall technical competency in the region.

“Mining doesn’t wait—and neither should sample processing,” said a spokesperson for Qingdao Decent Group. “Our container labs bring laboratory-grade precision to the most remote drill sites.”

With the growing global demand for critical minerals, on-site, real-time analysis has become a necessity for most mining companies. This means that mobile laboratories are becoming increasingly important as a supplement to traditional laboratories. Qingdao Decent Group’s Djibouti project sets a new benchmark for what’s possible in compact, rugged, and intelligent sample preparation.

For mining companies across East Africa—and beyond—this Mobile Mineral Processing Lab isn’t just convenient. It’s competitive advantage, delivered in a box.

As a premier provider of industrial and laboratory thermal equipment, Qingdao Decent Group continues to expand its global reach. With established projects across Africa, Southeast Asia, South America, and Australia, this Singapore delivery reinforces the company’s globalization strategy and expertise in serving high-tech laboratories with localized, responsive service.

Visit the DECENT Product Solutions homepageto view our full range of mobile container labs.