Qingdao Decent Group elevates internal expertise with mandatory grinding machine training. Recently, Qingdao Decent Group held a specialized training session on grinding machines and electrification projects. As part of the company’s long-term commitment to systematic product development training, this training was open to all employees. Its aim was to deepen understanding of the company’s core products through professional and detailed explanations, solidify professional foundations, and foster a corporate atmosphere where “everyone understands the products.”

The development of a product training system has always been a long-term project for the company, reflecting Qingdao Decent Group’s pursuit of high-quality products and professional strength. Through repeated professional empowerment, the entire team’s strength is united. Through systematic and in-depth explanations, every employee became a guardian and disseminator of product value, strengthening team cohesion and self-motivation to better provide high-quality DECENT products and services to global customers.

Strengthening Competitiveness Through Grinding Machine Training

The significance of the grinding machine training extends far beyond knowledge transfer. In an increasingly competitive global market environment, the most fundamental competitiveness stems from intrinsic professional competence. At Qingdao Decent Group, no matter if you’re on the R&D team, in production, sales, marketing, or management support—having a thorough grasp of our products is the cornerstone of boosting cross-departmental collaboration and delivering real value to our customers.

This systematic training approach doesn’t just ensure consistency in how we convey product value; it also guarantees that the core logic and key features behind our product R&D are accurately understood and shared across all business teams. After all, this kind of cross-functional alignment and collaboration isn’t just nice to have—it’s what keeps the entire company running smoothly and effectively.

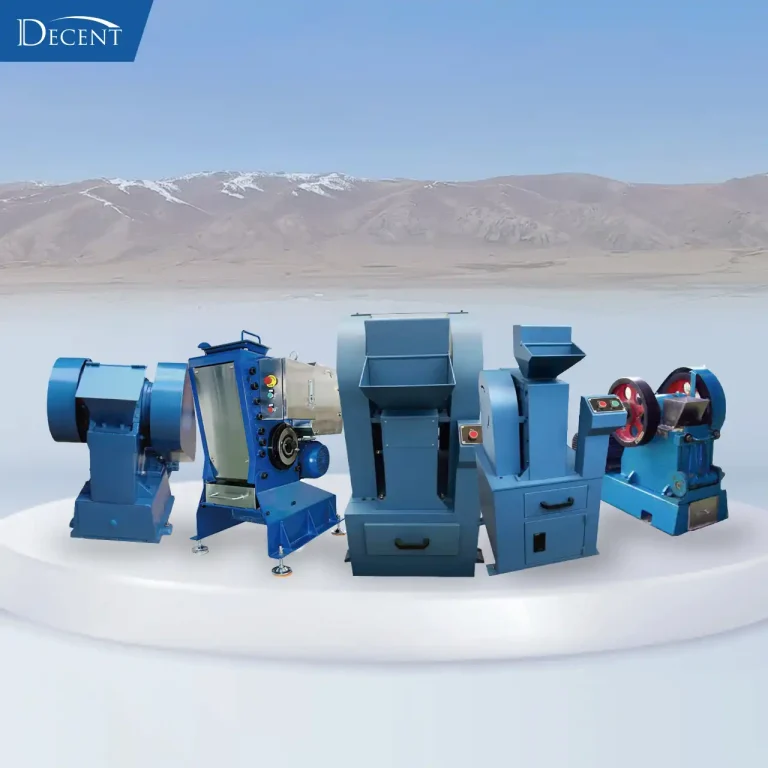

DECENT Grinding Mills: A Precision Tool for Sample Preparation

As the core equipment in the fine grinding process of mineral laboratory samples, the DECENT grinding mill is crucial for ensuring the accuracy of subsequent component analysis. Its performance stability, operational standardization, and maintenance adaptability directly affect the quality of laboratory data and operational efficiency. Without a precise sample, even the most advanced analytical instruments, such as atomic absorption spectrometers.

During the grinding machine training, the lead engineer first explained the key role of the grinding mill in the entire process of mineral exploration, development, and quality control from a macro perspective. Then, a detailed introduction to the DECENT grinding mill product system was provided, covering product model parameters, main technical features, selection logic for supporting components, relevant patented technologies, advantages of electrification device integration, standard operating procedures, and key points of daily maintenance. This gave the team a comprehensive understanding of the grinding mill product.

- Functions and Principles: This section provides an in-depth explanation of how the DECENT grinder, through efficient grinding motion, rapidly and uniformly prepares ore samples to the required fineness for analysis, emphasizing the scientific design’s role in ensuring sample representativeness and consistency.

- Models and Parameters: This section systematically introduces key parameters of different grinder models, including processing capacity, feed particle size, and final output fineness, helping employees understand how to recommend the most suitable model based on specific customer experimental needs.

- Core Component – Grinding Bowl: This section focuses on the grinding bowl used with the grinder. It details the applicable scenarios for different grinding bowl models, the characteristics of their materials (such as high manganese steel for heavy use, tungsten carbide for high purity, and zirconium oxide for minimal contamination), and their profound impact on grinding effect, sample contamination control, and equipment lifespan. Choosing the correct grinding bowl is often the most critical factor for accurate sample preparation.

- Innovation and Patents: This section showcases the numerous national patent certificates obtained for the DECENT grinding products. These patents provide authoritative evidence of the superior performance of the grinding machine in terms of structural appearance and operational safety.

- Operation and Maintenance: The training session featured product operation videos covering unpacking, installation preparation, grinding assistant installation, equipment startup, and operation, providing a clear demonstration of the grinding machine’s performance. Regarding vulnerable components, the instructor also provided detailed explanations of replacement time recommendations and procedures to extend equipment lifespan and reduce customer operating costs.

Electrification Devices: The “Smart Core” of Intelligence and Stability

Modern laboratory equipment has long transcended the scope of mechanical operation; the level of electrification and intelligence is a key indicator of equipment advancement. This grinding machine training gave equal importance to the supporting electrification devices (electrical systems) of the DECENT laboratory equipment.

- Integrated Control System: The training explained how the electrification devices achieve precise control of parameters such as grinding time, speed, and direction, as well as safety functions such as overload protection and abnormal alarms, ensuring the repeatability and reliability of the grinding process.

- Human-Machine Interface: This section briefly explains the relationship between motor selection, transmission efficiency, equipment operational stability, energy consumption, and noise levels, highlighting the Group’s high standards and stringent requirements for core power components.

- Power and Transmission: This section briefly explained the relationship between motor selection, transmission efficiency, equipment operational stability, energy consumption, and noise levels, highlighting the Qingdao Decent Group’s high standards and stringent requirements for core power components.

Professionalism Builds Quality

Qingdao Decent Group continuously invests resources in company-wide product training, the significance of which goes far beyond simply transferring knowledge. It clearly conveys the company’s core values and culture—true competitiveness is rooted in a deep understanding and continuous optimization of every detail of the product. This commitment is reflected in all our products, from this grinding mill to ourJaw Crusher Product Line.

Qingdao Decent Group will continue to deepen its product training system, expanding its breadth and depth of understanding, empowering every employee with a deeper understanding of products, serving global customers with more reliable equipment performance, and supporting the company’s steady progress in the global high-end laboratory equipment field with solid professional expertise. The successful completion of this rigorous grinding machine training program represents a significant step in this ongoing mission.