In 2013, Qingdao Decent Group led a transformative project to design and manufacture a fully transportable containerized laboratory that set the benchmark for on-site analytical capabilities. The challenge of the project was to manufacture a fully transportable 40’HQ containerized laboratory for advanced mineral sample preparation.

The delivery target is the Chinese branch of a world-leading inspection, identification, testing and certification company headquartered in Europe, and its core goal is to achieve efficient real-time mineral sample preparation.

By connecting the laboratory directly to the field, the analytical cycle is accelerated, the customer’s operational efficiency is significantly improved, and ultimately the customer’s competitive advantage in the rapidly developing mining and exploration field is enhanced.

Project Challenge: Integrating the required equipment in a containerized laboratory

This project was a landmark step for Qingdao Decent Group, and the main challenge was to integrate a full range of high-performance sample preparation equipment into the restricted and ever-changing environment of a standard container. This task required extremely meticulous space design to maximize every inch of space. The engineering team had to ensure that the overall layout was not only reasonable, but also convenient for smooth and ergonomic operation of the technicians.

All design choices must strictly adhere to international laboratory environmental, safety and operational standards. In order to meet the needs of convenient mobility, the laboratory renovation design must withstand the rigorous test of frequent transportation, ensuring the integrity of all equipment and the structural resilience of the container. This includes a sturdy installation solution and a reasonable structural layout to prevent any damage during transportation.

Ultimately, the presented solution needs to meet the electrical specifications of each device, as well as the customer’s operational requirements, so that the container laboratory can be put into use quickly after arriving on site.

Project Solutions: A fully customized, self-contained containerized laboratory

To meet these multifaceted challenges, Qingdao Decent Group fully utilized its extensive expertise in modular laboratory engineering and system integration. In the end, we created a complete mobile mineral sample preparation laboratory solution that achieved a breakthrough in on-site sample analysis. The containerized laboratory is equipped with a full set of advanced sample preparation equipment, and all components are carefully laid out to meet the specific needs of sample preparation, maximizing value in a limited space.

The integrated system includes:

- Drying oven with trolley: designed to simplify the drying process and minimize manual operation, thereby improving safety and efficiency.

- Jaw crusher: a necessary equipment for pre-crushing, which can operate continuously to improve efficiency.

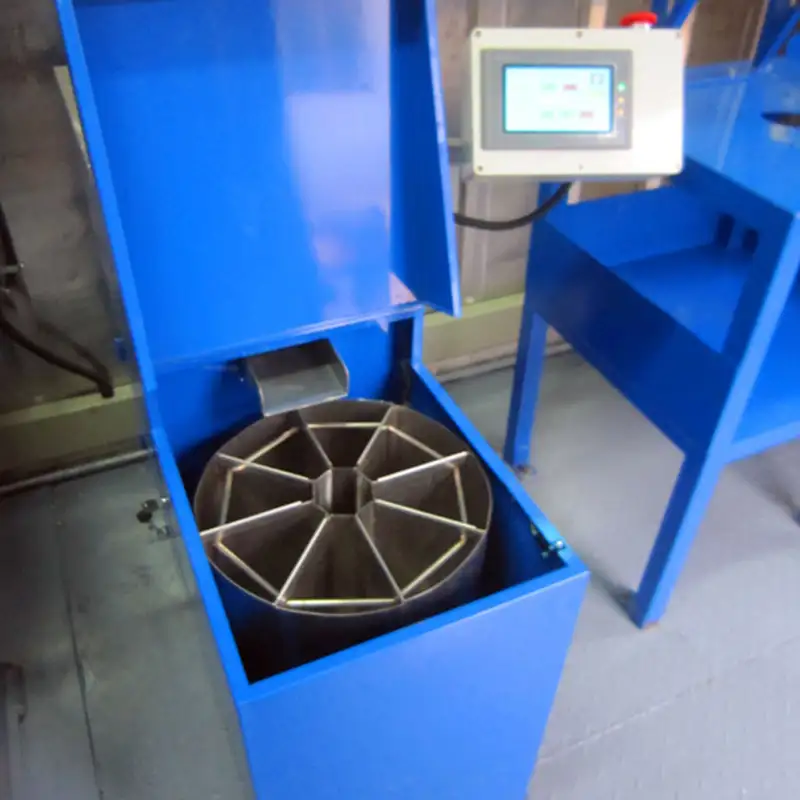

- Rotary sample divider: essential for obtaining highly representative subsamples to ensure the accuracy of subsequent analysis.

- Sample feeder: a feeding component that reduces manual burden and increases the output of the entire sample preparation line.

- Customized workbench: a workbench designed specifically for sample preparation, used for sample handling and other operations, ergonomic and easy to operate.

- Two pulverizers: high-performance equipment that optimizes workflow and minimizes dust generation.

The overall design concept of this integrated system is to reduce manual intervention, achieve high-throughput sample processing, and improve productivity.

In addition, DECENT team strictly follows the standards of sample preparation laboratories and designs and installs a customized ventilation system equipped with a high-efficiency pulse dust collector. Ventilation ducts are located throughout the laboratory and are directly connected to all dust-generating equipment, such as crushers and pulverizers. This is essential to ensure that technicians have a safe and clean working environment, protect them from airborne particles, and meet the requirements of health and safety regulations.

The electrical cabinets and lighting systems in the laboratory are also carefully designed to achieve energy saving and environmental protection, providing basic lighting and other functions for the laboratory. Throughout the implementation phase, DECENT team implemented strict product quality control and product testing procedures, from pre-installation inspection to full system operation test, to ensure that the laboratory meets all functional and usage requirements before final delivery.

Customer Feedback: A successful cooperation

The containerized laboratory project was successfully completed and delivered in 2013, winning high praise from the customer. The customer expressed great satisfaction with the final container laboratory and highly praised the professional team, efficient project management and excellent customization capabilities of Qingdao Decent Group.

The project proved that high-performance and complex laboratories can be fully mobile without compromising safety, efficiency and analytical quality. The project was a huge success and brought unparalleled operational flexibility to the customer.

In the future, Qingdao Decent Group will take this project as a starting point to deepen its layout in the field of mobile container laboratories and provide more breakthrough customized solutions for more global laboratories and industries. We are committed to working with new partners and customers to contribute to the progress of global scientific research and mining laboratories.