Achieving consistent, homogeneous blending of dry powders and granular materials is critical for product quality and process efficiency in countless industries, from pharmaceuticals to food and chemicals.Traditional mixing methods can often lead to particle segregation, uneven distribution, or even damage to fragile materials, compromising the integrity of the final product. The need for a reliable, gentle, and thorough blending solution is paramount.

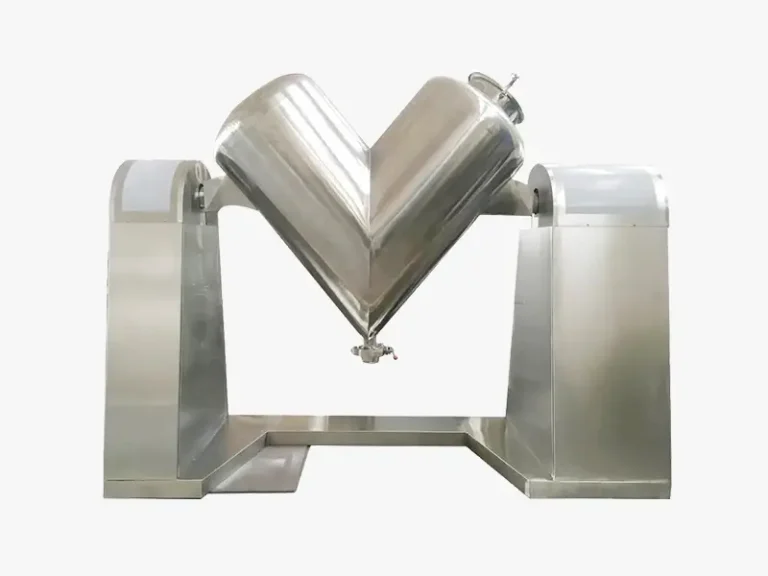

The DECENT V Type Mixer offers an exceptional solution, engineered for superior performance. Its distinctive V-shaped design and unique tumbling action ensure materials continuously split and recombine in a three-dimensional flow, providing unparalleled blending uniformity without dead corners.This gentle yet highly effective mixing process makes the V Type Mixer ideal for delicate or easily segregated ingredients, guaranteeing precise results, complete discharge, and easy cleanup for optimized production workflows.

| Model | DVM50 | DVM100 | DVM150 | DVM200 | DVM300 |

| Vessel Volume(L) | 50 | 100 | 150 | 200 | 300 |

| Working Volume (L) | 20 | 40 | 70 | 100 | 150 |

| Power (kW) | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 |

| Overall Dimension (mm) | 1420x600x1160 | 1500x600x1200 | 1800x700x1600 | 2100x700x1600 | 2600x800x2000 |

| Mixing Time (minute) | 8-20 | 8-20 | 10-20 | 15-20 | 15-20 |

To find out more about our products and solutions, please fil out the form below and one of our experts wil get back to you shortly.