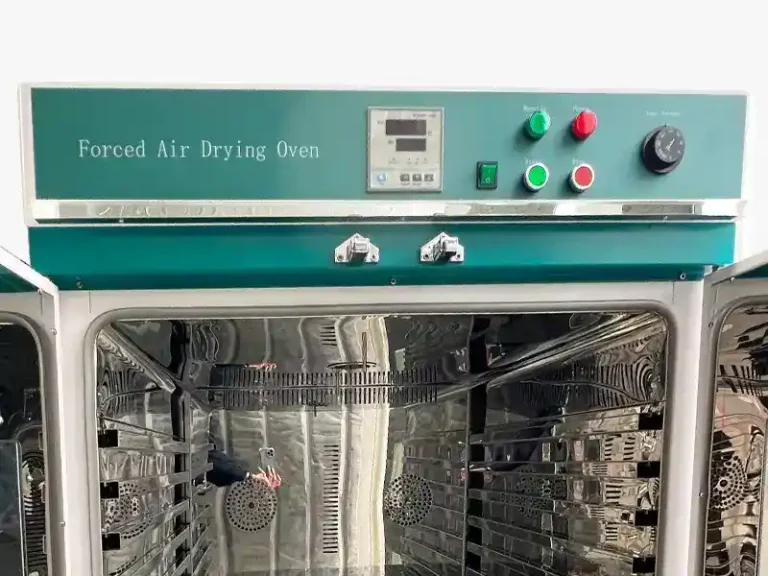

For industries and large-scale laboratories where throughput and efficiency are paramount, the DECENT Large Electric Forced Air Drying Oven delivers exceptional performance. This robust oven is engineered to handle substantial volumes of materials, from components and chemicals to glassware and industrial parts, making it an indispensable asset for high-demand thermal processing.

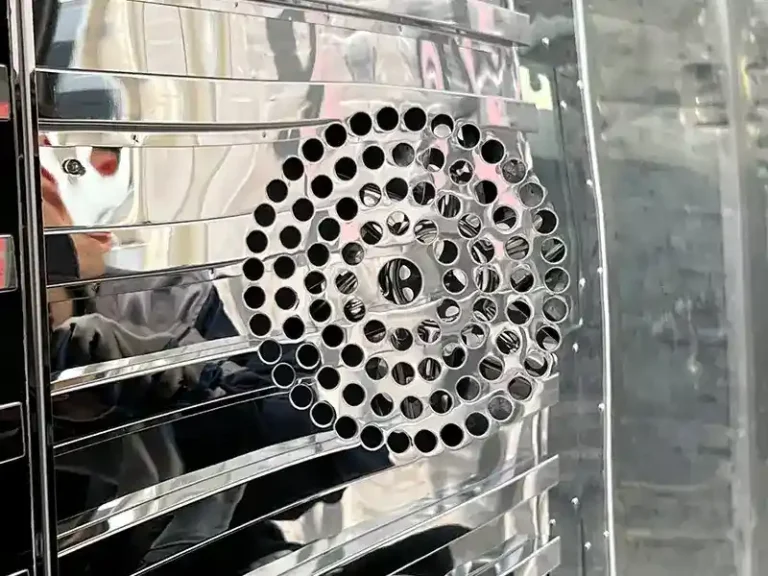

Leveraging powerful forced air circulation, it ensures that every corner of its spacious chamber receives consistent, uniform heating, eradicating cold spots and dramatically accelerating drying, curing, baking, and sterilization cycles. Choosing a Large Electric Forced Air Drying Oven from DECENT Group means investing in a solution that combines immense capacity with precision, ensuring optimal results and increased productivity for your most extensive applications.

The DECENT Large Electric Forced Air Drying Oven is built to withstand the rigors of continuous, heavy-duty operation while maintaining the critical precision required for sensitive processes. Its expansive internal volume makes it perfectly suited for applications such as batch drying of pharmaceutical powders, pre-heating large electronic assemblies, curing industrial coatings, or sterilizing numerous medical instruments simultaneously. The advanced electric heating system, combined with a high-performance fan, facilitates rapid heat-up times and quick temperature recovery even after loading, minimizing downtime.

Typically featuring a durable stainless steel interior for corrosion resistance and an insulated double-wall construction for energy efficiency, this Large Electric Forced Air Drying Oven is designed for longevity and consistent, reliable performance in the most demanding environments. Intuitive digital controls offer precise temperature management and programmable cycles, ensuring ease of use and adherence to stringent operational protocols.

| Models | DDO4A | DDO5A | DDO6A | DDO7A | DDO8A | |

| DDO4AB | DDO5AB | DDO6AB | DDO7AB | DDO8AB | ||

| Circulation Mode | Forced Convection | |||||

| Performance | Temperature Range | RT+10-250℃ | RT+10-300℃ | |||

| Temperature Resolution | 0.1℃ | |||||

| Temperature Fluctuation | ±1℃ | |||||

| Temperature Distribution Accuracy | ±3% | |||||

| Structure | Workspace | Model A: Iron Inner Liner, Model AB: Stainless Steel Inner Liner | ||||

| Outer Casing | Processed with galvanized sheet and electrostatic spray coating for anti-corrosion treatment | |||||

| Insulation Layer | High-quality rock wool board (CE certification) | |||||

| Heater | Stainless Steel Electric Heating Tube | |||||

| Rated Power | 6kW | 6.6kW | 9kW | 12kW | 15kW | |

| Exhaust Vent | Top or Side Exhaust | |||||

| Controller | Temperature Control Method | PID Intelligent Control | ||||

| Temperature Setting Method | Keypad Setting | |||||

| Temperature Display Method | LCD Digital Display | |||||

| Timer | 0-9999 minutes (with timed waiting function) | |||||

| Operation Functions | Fixed value operation, timed operation, automatic stop | |||||

| Additional Functions | Temperature Deviation Correction, Menu Locking, Power-Off Memory | |||||

| Sensor | pt100 | |||||

| Safety Device | One-Key Start, Over-Temperature Power Off | |||||

| Specifications | Workspace Dimensions (WxDxH mm) | 800*800*1000 | 1000*1000*1000 | 1000*1000*1300 | 1200*1200*1300 | 1600*1200*1600 |

| External Dimensions (WxDxH mm) | 940*1000*1400 | 1040*1200*1400 | 1230*1200*1670 | 1330*1400*1670 | 1750*1400*1990 | |

| Packaging Dimensions (WxDxH mm) | 1060*1090*1520 | 1260*1290*1520 | 1350*1300*1890 | 1550*1500*1890 | 1950*1500*1910 | |

| Internal Volume | 640L | 1000L | 1300L | 1870L | 3070L | |

| Number of Shelves | 11 | 11 | 15 | 15 | 18 | |

| Shelf Load Capacity | 30KG | |||||

| Shelf Spacing | 70MM | |||||

|

Power (50/60Hz) Rated Current |

380V | |||||

| Net Weight / Gross Weight (kg) | 200 | 260 | 350 | 480 | 800 | |

| Accessories | Shelf | 2 | ||||

| Shelf Racks | None | |||||

| Configurable for Additional Setup | Shelf, RS485 Interface, Printer, Programmable Temperature Controller | |||||

To find out more about our products and solutions, please fil out the form below and one of our experts wil get back to you shortly.

QINGDAO DECENT GROUP consists of Decent Group Limited, Qingdao Decent Electromechanical Tech Co., Ltd., Qingdao Mars Labtech Co., Ltd. and Hunan Kilnsware Industrial Ceramics Co., Ltd.