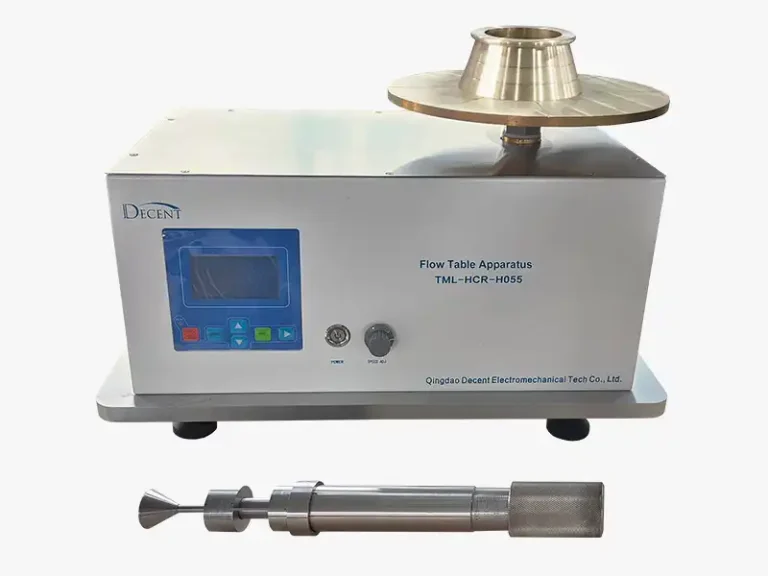

The DECENT TML Flow Table Apparatus, also known as the Intelligent Flow Disc Tester, is a critical instrument designed to enhance safety in the global maritime transport of solid bulk cargoes. Its primary function is to accurately determine the Transportable Moisture Limit (TML) of materials prone to liquefaction, such as mineral concentrates and coal. Liquefaction poses a severe risk, as it can cause cargo shifts and destabilize vessels at sea, leading to catastrophic accidents.

This apparatus is engineered to be in full compliance with the rigorous experimental requirements of the International Maritime Solid Bulk Cargoes (IMSBC) Code, making it an indispensable tool for ensuring adherence to international safety regulations. By providing a reliable and precise method for TML determination, the DECENT TML Flow Table Apparatus empowers shipping companies, inspection agencies, and laboratories to prevent potential hazards and uphold the highest standards of maritime safety.

The DECENT TML Flow Table Apparatus stands out for its combination of high precision, easy operation, and durable stability, ensuring consistent and reliable results. Featuring a robust mechanical vibration mode, the apparatus precisely simulates the dynamic conditions that bulk cargoes experience during a voyage, with a consistent vibration amplitude of 12.5 mm. Operators can fine-tune the test parameters with an adjustable RPM from 1 to 50 rpm/min, allowing for tailored testing based on specific cargo characteristics.

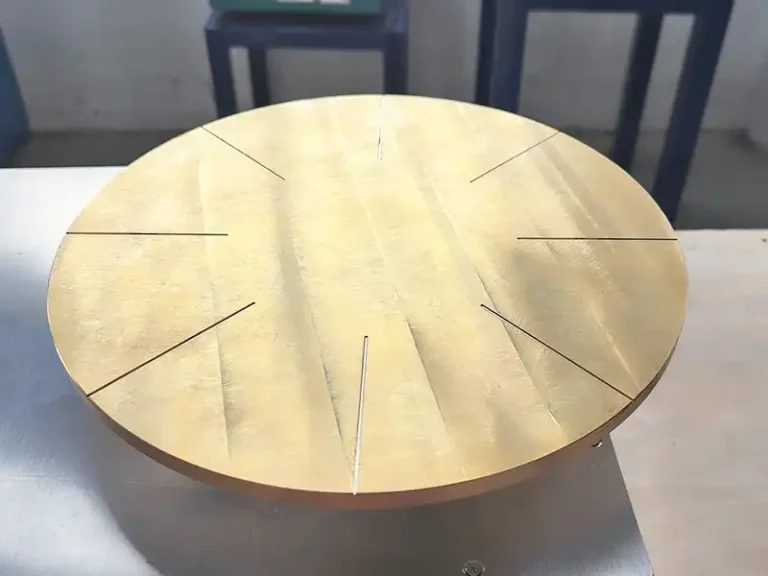

The manual pressing mode ensures a controlled and repeatable sample preparation process on its 254mm diameter plate. This intuitive design, coupled with its reliable performance, makes the TML Flow Table Apparatus a convenient and efficient solution for any laboratory focused on cargo safety. DECENT Group’s commitment to quality ensures that this apparatus will provide long-term, dependable service, safeguarding cargo and crew across every shipment.

| Voltage | Power | Vibration Mode | Vibration Amplitude (mm) | RPM | Pressing Mode | Plate Diameter (mm) | Vibration Frequency |

| 220V/50Hz | 40W | Mechanical | 12.5 | 1-50 rpm/min | Manual | 254 | 50/2 min |

To find out more about our products and solutions, please fil out the form below and one of our experts wil get back to you shortly.