In a myriad of industrial processes—from grinding, polishing, and mixing to woodworking and material handling—the generation of airborne dust and fine particulates is an unavoidable reality. These suspended contaminants pose significant health risks to workers, reduce visibility, damage sensitive machinery, and often lead to costly regulatory non-compliance. Addressing these challenges effectively requires a dedicated and powerful air purification solution.

The DECENT DDC-JZ Series Dust Removal Unit is specifically designed as a comprehensive industrial dust collection system. Engineered to capture and filter a wide range of dry dusts and non-fibrous particulates, this unit plays a pivotal role in maintaining pristine air quality, ensuring a safer and healthier working environment for your personnel, protecting valuable equipment from abrasive dust, and contributing to overall operational efficiency in various factory settings.

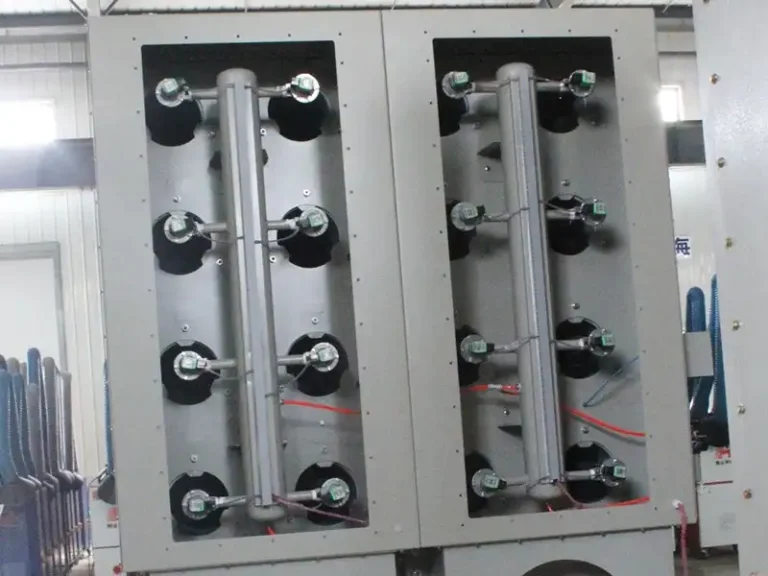

The DECENT DDC-JZ Series Dust Removal Unit combines formidable suction power with advanced multi-stage filtration to deliver exceptional performance in demanding industrial applications. Typically employing high-efficiency filter cartridges with automatic pulse-jet cleaning, this system ensures continuous, clog-free operation and extended filter lifespan, maintaining consistent airflow and filtration effectiveness. Its robust construction, often featuring a durable steel casing and wear-resistant components, allows it to withstand the rigors of heavy industrial use.

The modular design of the Dust Removal Unit enables versatile integration with various industrial processes, effectively collecting dust from grinding booths, cutting stations, conveying systems, and more. With its powerful fan and optimized air intake design, the DDC-JZ Series provides a reliable and efficient solution for controlling dust pollution, safeguarding both worker health and the longevity of your industrial machinery.

| Series | Airflow (m3/ h) | Power (kW) | Voltage (V) | Filter Cartridge Qty | Filter Size (mm) | Cleaning Mode of Filter Cartridge | Noise dB (A) | Body Size (mm) |

| DDC-JZ08 | 10000 | 11 | 380 | 8/ set | φ325×1000 | Pulse | N/A | 1100*1700*3500 |

To find out more about our products and solutions, please fil out the form below and one of our experts wil get back to you shortly.