In industries like mining, construction, coal processing, and metallurgy, efficient and precise material size reduction is fundamental.Whether preparing raw materials for further processing or creating aggregates with specific characteristics, the choice of crushing equipment significantly impacts operational efficiency and product quality. Many materials, especially those that are medium-hard, brittle, or even somewhat sticky, present challenges for conventional crushers, often leading to excessive fine particles or inconsistent output.

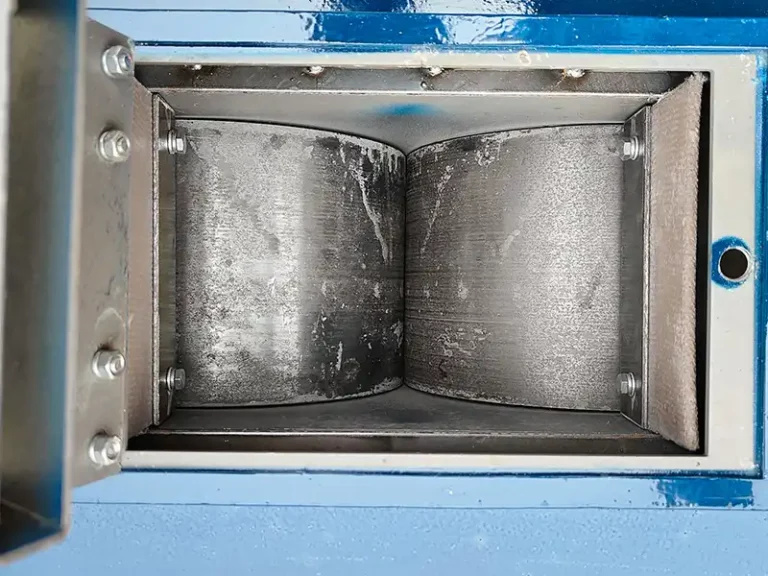

The DECENT Double Roller Crusher provides a powerful and adaptable solution designed to overcome these hurdles. Utilizing a combination of compression and shear forces between two counter-rotating rolls, this machine expertly breaks down materials to a desired particle size, ensuring a uniform, cubical product while minimizing unwanted fines. It stands as an indispensable asset for operations demanding reliable performance and precise control over their crushed output.

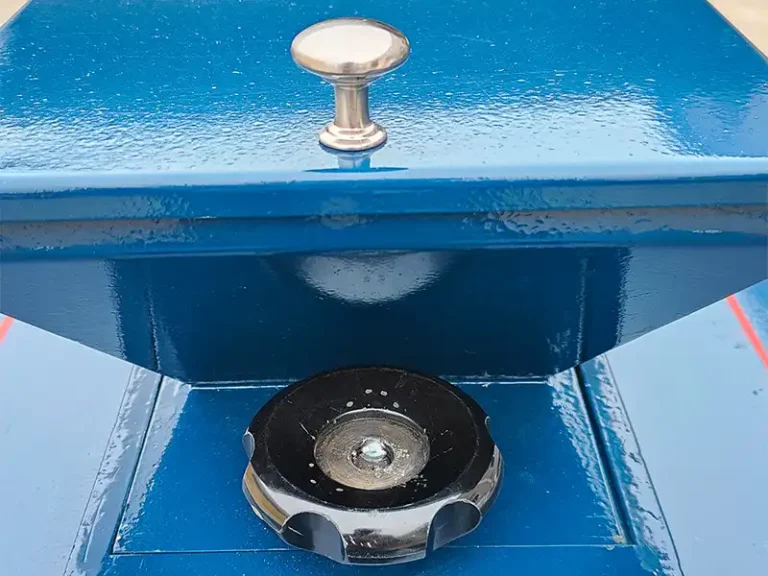

The DECENT Double Roller Crusher is engineered for versatility and robust performance. It efficiently processes a wide array of materials including coal, coke, limestone, gypsum, salt, clay, and various ores. Its unique operating principle allows it to effectively handle sticky and wet feeds, a common challenge for other crusher types, without experiencing clogging. The gap between the two rollers can be easily adjusted, providing precise control over the final product size, making it suitable for primary, secondary, or even tertiary crushing stages.

Designed for continuous operation, this crusher boasts excellent reliability and requires minimal maintenance due to its simplified structure and wear-resistant components. Furthermore, features like integral tramp relief allow uncrushable objects to pass through without damaging the machine, ensuring uninterrupted operation and safeguarding your investment. The Double Roller Crusher delivers a high throughput with low energy consumption, contributing to reduced operational costs and a more sustainable process.

| Model No. | DRC20075 | DRC200125 | DRC200150 | DRC250150 |

| Roller Size | Φ200x75mm | Φ200x125mm | Φ200x150mm | Φ250x150mm |

| Feed-in Size | ≤13mm | ≤13mm | ≤13mm | ≤20mm |

| Output Size | <3-0.5mm | <3-0.5mm | <3-0.5mm | <3-1mm |

| Productivity | 300-200 kgs/h | 350-250 kgs/h | 400-300 kgs/h | 450-300 kgs/h |

| Power | 1.5 kw | 3 kw | 3 kw | 3 kw |

| Voltage | 3ph, 380v, 50hz | 3ph, 380v, 50hz | 3ph, 380v, 50hz | 3ph, 380v, 50hz |

| Weight | 220 kgs | 240 kgs | 260 kgs | 280 kgs |

| Overall Dimension | 820x490x960mm | 820x540x960mm | 840x550x960mm | 840x560x960mm |

To find out more about our products and solutions, please fil out the form below and one of our experts wil get back to you shortly.