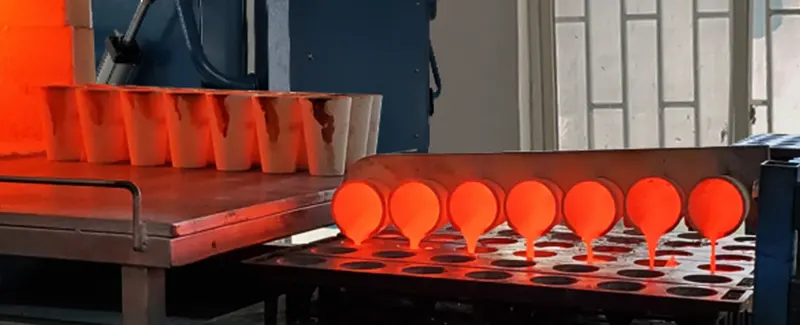

The critical step of pouring molten material from DECENT fire assay crucibles into iron molds, a key stage in precious metal recovery and refining.

Fire Assay Clay Crucibles: A Comprehensive Solution Reference

Fire assay is a traditional, highly accurate, and widely used method for determining the precious metal content (primarily gold, silver, and platinum group metals) in various materials, including ores, concentrates, and recycled materials. At the heart of this process lies the fire assay clay crucible, a specialized refractory vessel designed to withstand extreme temperatures and corrosive environments.

This article offers a comprehensive solution framework for fire assay clay crucibles, consolidating practical insights from Qingdao Decent Group’s industry experience.

1. Definition

A fire assay clay crucible is a ceramic container specifically engineered from a unique blend of fire clay and proprietary additives. Its primary function is to serve as the reaction vessel during the fusion stage of the fire assay process, where a sample containing precious metals is mixed with fluxes and subjected to high temperatures in a furnace. The crucible facilitates the melting of the sample, allowing for the collection of precious metals into a lead button, separated from the waste material (slag).

Unlike single-use disposable crucibles, high-quality fire assay clay crucibles are often designed for multiple firings, offering cost-effectiveness and sustained performance.

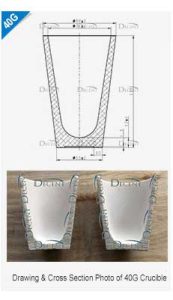

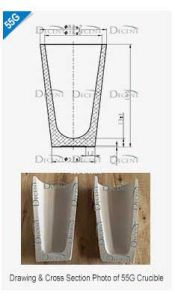

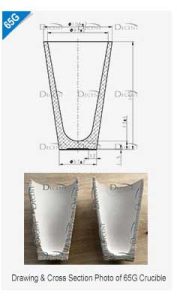

Technical Parameters of Conventional DECENT Fire Assay Crucibles

| Model No. | Top OD (mm) | Base OD (mm) | Height (mm) | Pcs/Crate | Crate /20′ Container |

| DCC20 | 76 | 46 | 98 | 3000 | 20 |

| DCC30 | 85 | 56 | 105 | 2574 | 20 |

| DCC40 | 90 | 56 | 135 | 2000 | 20 |

| DCC50 | 105 | 56 | 150 | 1530 | 20 |

| DCC55 | 90 | 56 | 155 | 1500 | 20 |

| DCC65 | 105 | 56 | 165 | 1400 | 20 |

| DCC75L | 120 | 75 | 160 | 1000 | 20 |

| DCC75S | 110 | 60 | 200 | 840 | 20 |

| DCC75I | 125 | 61 | 210 | 672 | 20 |

| AC1 | 105 | 56 | 130 | 880 | 20 |

| AC2 | 110 | 70 | 130 | 880 | 20 |

2. Formula (Material Composition)

The performance of a fire assay clay crucible is heavily dependent on its precise material composition. A typical formula for high-quality crucibles involves:

- Fire Clay Powder (Coarse): Approximately 80%

- Kaolin Clay Powder (Fine Binder): Approximately 20%

- Water: 2-5% for pressing, up to 20% for plastic forming.

- Proprietary Additives: These are crucial for enhancing specific properties such as thermal shock resistance, corrosion resistance, and non-wetting characteristics.

Key Chemical Composition (Approximate Percentages for High-Quality DECENT Crucibles):

- Silica (SiO₂): 60%-65%

- Aluminum Oxide (Al₂O₃): 30%-34%

- Ferric Oxide (Fe₂O₃): <2% (Low iron content is desirable to prevent contamination and improve performance)

- Titanium Oxide (TiO₂): <2%

- Calcium Oxide (CaO): <0.6%

- Magnesium Oxide (MgO): <0.2%

- Sodium Oxide (Na₂O): <0.1% (Low caustic soda content is critical)

- Potassium Oxide (K₂O): <0.5%

The precise blend of these materials, particularly the high silicon content, low caustic soda, and low iron content, contributes to the crucible’s ability to withstand extreme thermal and chemical stresses.

3. Production Process

The manufacturing of fire assay clay crucibles involves a meticulous, multi-stage process, often utilizing advanced automated technology for consistency and quality.

- Raw Material Preparation:

- High-purity raw materials (fire clay, kaolin, additives) are carefully selected.

- Materials are ball milled to achieve specific particle size granulation. Combining different particle sizes (coarser for strength, finer for density) is essential for optimal thermal shock resistance and a dense structure.

- The raw materials are thoroughly blended in precise proportions to create a homogeneous mix.

- Forming:

- The prepared clay mixture is formed into the desired crucible shape. Common methods include:

- Curing and Pressing (Stamping Forming): This method utilizes immense pressure from automated machinery to create a dense, high-strength body and ensure consistent sizing.

- Roll Forming (Plastic Forming): This involves shaping the clay on a rolling mechanism.

- The prepared clay mixture is formed into the desired crucible shape. Common methods include:

- Drying:

- Crucibles are left to dry slowly for several hours. This critical step prevents cracking caused by rapid water evaporation. Controlled drying ensures the crucible is completely dry before firing.

- Firing (Sintering):

- Dried crucibles are placed in a high-temperature kiln (typically heated to around 1000°C to 1650°C, depending on the desired properties and materials).

- The firing process is carefully controlled with a slow heating rate, holding at certain temperatures (biscuit firing), and a slow cooling rate to prevent cracking and achieve optimal strength and durability.

- Quality Control:

- Throughout the production, strict quality control measures are implemented, including visual inspections, dimensional checks, and performance testing.

4. Video

Production Process of DECENT Fire Assay Clay Crucibles

5. Characteristics

High-quality fire assay clay crucibles possess several crucial characteristics that ensure their effectiveness and reliability in precious metal analysis:

- High Refractoriness: Capable of withstanding extremely high temperatures, typically up to 1400°C - 1650°C, without deforming or degrading.

- Excellent Thermal Shock Resistance: Engineered to withstand rapid and severe changes in temperature during heating and cooling cycles without cracking or breaking. This is crucial for repeated use.

- High Mechanical Strength: Possessing a dense, robust body that resists physical impact and handling during the assay process.

- Exceptional Chemical Stability and Corrosion Resistance: Able to withstand the highly corrosive environment created by fluxes and molten samples without reacting or contaminating the assay.

- Non-Wetting Properties: Prevents the molten lead button containing precious metals from sticking to the crucible walls, ensuring complete recovery.

- Consistent Crucible Size: Achieved through automated manufacturing, which is critical for multi-pour systems and automated laboratory lines.

- Multiple Use Capability: Designed for repeated firings (often 5-9 times or more with certain flux formulas), significantly reducing the cost per firing and increasing profitability.

- Low Precious Metal Content: Extremely low levels of gold, silver, and other elements in the crucible material to prevent contamination of the assay results.

- Smooth Interior Surface: Facilitates the clean separation of the lead button from the slag.

- No Slagging or Penetration: Prevents the molten slag from adhering to or penetrating the crucible walls, ensuring clean pouring and accurate results.

6. Testing

Rigorous testing is performed at various stages of production and on finished products to ensure the quality and performance of fire assay clay crucibles.

- Visual and Physical Inspection:

- Checking for cracks, defects, and foreign particles.

- Measuring wall thickness, height, and diameter to ensure consistent sizing.

- Weighing crucibles to detect variations.

- Testing durability by gradually increasing impact force.

- Cutting crucibles in half to check for consistency of grain size and internal structure.

- Usage Testing (Simulated Fire Assay):

- Randomly selected crucibles are subjected to simulated fire assay conditions.

- Flux (often without silica for aggressive testing) and a sample are added.

- Crucibles are placed in a fusion furnace at typical operating temperatures (e.g., 1050°C) for a specified duration (e.g., 1 hour).

- This process is repeated multiple times (e.g., 5 times or more).

Pass Criteria:

- No noticeable difference in pouring characteristics.

- No lead splashing on the molds.

- No structural damage (cracks, holes) to the crucible walls.

- Clean separation of the lead button from the slag.

- Thermal Shock Resistance Test:

- Crucibles are subjected to rapid heating and cooling cycles between extreme temperatures (e.g., 1300°C to room temperature) to evaluate their resistance to cracking.

- Chemical Compatibility/Corrosion Resistance Test:

- Exposing crucibles to various flux compositions and molten metals to assess their resistance to chemical attack and ensure non-contamination.

- Refractoriness Under Load (RUL) Test:

- Determining the temperature at which the crucible deforms under a specific load, indicating its high-temperature strength.

7. Packaging and Shipping

Effective packaging and shipping are crucial to ensure fire assay clay crucibles arrive at their destination in perfect condition, ready for use.

- Packaging Materials:

- Inner Protection: PE bags, silver-foiled, or pure aluminum paper packing to protect individual crucibles from moisture and abrasion.

- Outer Cartons: Five-storey corrugated cartons provide robust protection during transit.

- Pallets: Wooden pallets or plastic pallets are used for larger quantities to facilitate handling and prevent damage during stacking and transportation.

- Packing Density: Crucibles are often designed for "nesting" to optimize space utilization in warehouses and minimize transport costs.

- Shipping Practices:

- Secure Loading: Products are carefully loaded into shipping containers to prevent movement and damage during transit.

- Labeling: Clear labeling with product information, handling instructions, and safety warnings.

- Lead Time: Reputable manufacturers maintain stock for popular models, allowing for short order lead times (e.g., 5-7 days for urgent orders) and efficient delivery.

- Shipping Channels: Various options like express courier (DHL, EMS, FedEx, Aramex) for smaller orders or sea/air freight for larger shipments, ensuring efficient and secure delivery.

- Insurance: Shipments are often insured against damage or loss during transit.

8. Relevant Content & Applications

The Fire Assay Method:

The fire assay clay crucible is integral to the first step of the fire assay process, which generally involves:

- Fluxing and Fusion:

- A finely pulverized sample is mixed with a precisely formulated flux (e.g., borax, soda ash, silica, litharge) and often silver as a collector.

- This mixture is placed into the clay crucible and heated in a fusion furnace at temperatures typically ranging from 850°C to 1060°C for about 60 minutes.

- During fusion, the lead in the flux captures precious metals, forming a dense lead alloy (lead button) that sinks to the bottom of the crucible.

- Unwanted gangue materials react with fluxes to form a lighter slag that floats on top.

- The molten material is then poured into a cast iron mold, and upon cooling, the lead button is separated from the slag.

- Cupellation:

- The lead button is placed in a porous bone ash or magnesia cupel and heated in a muffle furnace (around 1000°C).

- The lead oxidizes and is absorbed into the cupel, leaving behind a pure bead (prill) of gold, silver, and other noble metals.

- Parting (for Gold and Silver):

- The prill is treated with nitric acid to dissolve silver, leaving behind solid gold.

- The gold is then washed, dried, and weighed to determine its content. Silver content is determined by difference or by analyzing the nitric acid solution.

- Analysis:

- The gold/silver content can be determined gravimetrically (by weighing) or by instrumental methods such as Flame Atomic Absorption (AA), Inductively Coupled Plasma-Optical Emission Spectrometry (ICP-OES), or Inductively Coupled Plasma-Mass Spectrometry (ICP-MS).

Applications of Fire Assay Clay Crucibles:

- Mining and Exploration: Analyzing drill cores, soil samples, and rock fragments to assess gold and precious metal concentrations in potential mining sites and track recovery rates.

- Assay Laboratories and Refineries: Daily testing to determine the purity of precious metals (gold, silver, PGMs) in bullion, scrap, and other materials.

- Jewelry Production: Quality control to ensure finished pieces meet purity standards.

- Environmental Monitoring: Measuring trace amounts of precious metals in soil and water samples.

- Catalysis: Determining precious metal loading in automotive catalytic converters and industrial catalysts.

- Recycling: Recovering precious metals from electronic waste and other waste streams.

This comprehensive overview decisively highlights the critical and revolutionary role of DECENT fire assay clay crucibles in the accurate, reliable, and cost-effective determination of precious metals, all underpinned by rigorous manufacturing processes, uncompromising quality control from Qingdao Decent Group, and a commitment to unmatched performance. Choosing the right crucible is paramount for the success of any precious metal assay.

Internal Link Suggestions:

- Explore our full range of DECENT Fire Assay Consumables

- View DECENT Fire Assay Crucibles and Magnesia Cupels

- Learn about Qingdao Decent Group's Manufacturing Facilities