When a major mining company in the Philippines approached Qingdao Decent Group, we knew this magnetic separation pilot plant project would test our ability to deliver precision engineering under demanding conditions. The client required a complete pilot plant system capable of processing 3 tons of ore per day across 8-hour shifts—no room for error, no compromise on safety, and zero tolerance for substandard performance.

Magnetic Separation Pilot Plant Project: Putting Customer Requirements First

Understanding the Philippine Client’s Critical Needs

From the moment we received the client’s request, the DECENT team thoroughly understood the challenges facing the Philippine mining industry, including the tropical climate, unstable ore composition, and strict regulations. Our client needed a pilot plant that would:

- Process 3 tons of material daily with absolute reliability

- Operate continuously in high-humidity environments

- Meet all Philippine occupational safety standards

- Provide accurate data for scaling to full production

Qingdao Decent Group’s design process began with a physical assessment of the operating site. Ultimately, based on the overall environmental impact, we selected equipment components made of corrosion-resistant materials to minimize the impact of high temperature and high humidity environments.

Magnetic Separation Pilot Plant Project: Customized Solution

For this groundbreaking project, our engineering team designed a customized solution to meet the specific operational needs of the Philippine client, prioritizing operational safety.

Qingdao Decent Group offers durable industrial magnetic drums, essential for efficient material separation in various processing applications.

Qingdao Decent Group offers robust industrial ball mills, like this blue unit, designed for efficient grinding and processing of various materials.

Close-up of the robust gear system on a Qingdao Decent Group industrial ball mill, highlighting the precision and durability of ore processing equipment.

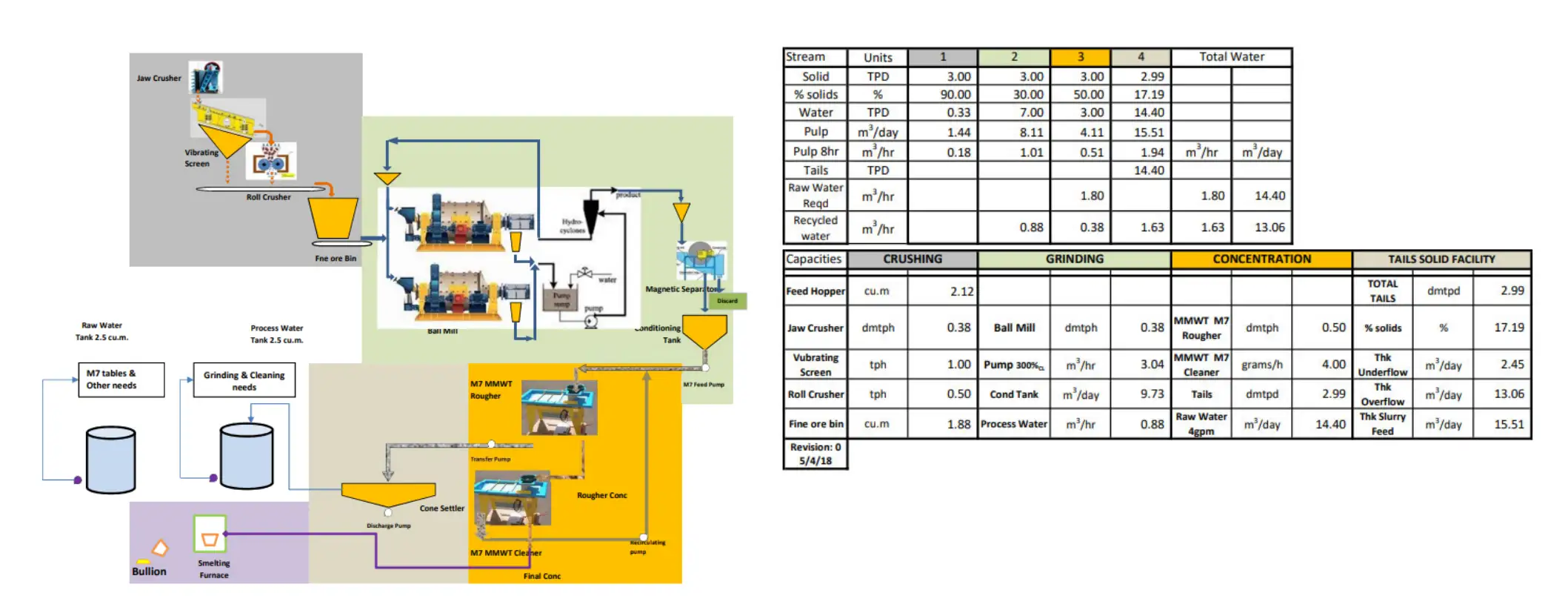

The complete system included:

- Primary Crushing System

- DECENT Jaw Crusher: Engineered to handle 45mm feed size while producing consistent 20mm output at 1 ton per hour

- Integrated Vibrating Screen: Featuring 10mm nominal sieve openings with corrosion-resistant mesh

- Safety-First Design: Elevated platform with metal stair access, comprehensive electrical controls, and emergency stop systems

- Material Handling Solution

- Custom Conveyor System: 0.4-meter wide 3-ply troughed belt with precisely calculated 18-degree incline

- Safety Integration: Full-length steel catwalk, pull-wire emergency stops, and comprehensive guarding at all pinch points

- Power Management: 3HP variable frequency drive system ensuring smooth material transfer between stages

- Secondary Processing Equipment

- DECENT Roll Mill: Precision-engineered to reduce 20mm feed to 10mm product with conical fine ore bin

- Dual Ball Mill System: Complete with hydrocyclone classifier, slurry pumps, and variable speed control

- Steel Ball Optimization: Custom mix of cast iron and forged steel balls in multiple sizes for optimal grinding efficiency

- Magnetic Separation System

- DECENT Magnetic Separator: Permanent magnetic drum with ultra-high magnetic force for maximum mineral recovery

- Process Integration: Complete sump boxes, concentrate handling, and electrical systems designed for Philippine power specifications

Magnetic Separation Pilot Plant Project: Safety as Non-Negotiable Priority

In Philippine mining operations, safety isn’t just regulatory compliance—it’s a moral obligation. Our engineering team incorporated safety features at every stage:

- Electrical Systems: All components rated for 220V/3-phase with moisture-resistant connections

- Mechanical Protection: Comprehensive guarding on all moving parts accessible to personnel

- Emergency Controls: Strategically placed emergency stops along the entire processing line

- Material Handling: Safe transfer points between equipment to prevent spillage and dust generation

Magnetic Separation Pilot Plant Project: Overcoming Implementation Challenges

To address the practical operational challenges posed by the local hot and humid environment, Qingdao Decent Group implemented the following measures:

- Humidity suppression: To withstand hot and humid environments, all electrical components are coated with a special moisture-proof coating to ensure continuous operation of each device.

- Anti-corrosion: The housing of DECENT crusher and other equipment is made of high-quality stainless steel to ensure smooth operation.

- Maintenance Access: Service platforms designed for safe technician access in all weather conditions

After the equipment was manufactured, the DECENT engineering team conducted a two-week commissioning phase to ensure that each device and component was operating stably and efficiently as expected.

“The DECENT system performed exactly as promised,” reported the client’s operations director. “What surprised us most was their ability to anticipate potential operational issues and provide us with alternative solutions.”

A magnetic separation pilot plant is a critical bridge between laboratory analysis and full-scale production, crucial for delivering reliable data. The successful implementation of the magnetic separation pilot plant designed and manufactured by Qingdao Decent Group for a client in the Philippines demonstrates our commitment to providing advanced solutions that improve efficiency and optimize production capacity for clients worldwide. Qingdao Decent Group is committed to providing clients with not only laboratory equipment but also comprehensive support from initial consultation to final project implementation.

Related DECENT Projects: